ALL NEWS :

Punt Dal Gall

01/06/2017 - posted in HYDRO

Designing obturator sealing system to renovate guard gate and protect contributors: This was the challenge that PXL SEALS took up, on the impressive Punt Dal Gall dam. Which were the main steps to handle this project successfully? Discover how PXL Seals designed, manufactured and installed the (...)

EN SAVOIR PLUS

The main advantages of PXLKOT materials

19/04/2017 - posted in HYDRO

For more than 20 years, PXL Seals appears as one of the major suppliers at high stake sealing solutions, mainly for hydropower applications. If we consider seals as major components to ensure the proper operation of a mechanical system, they are associated to other strategic components among which (...)

EN SAVOIR PLUS

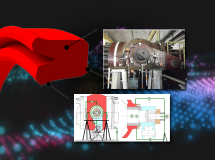

Hydroelectric turbines of the future

16/06/2016 - posted in HYDRO

As a partner of the main plant operators and manufacturers in the world, PXL SEALS has chosen to organise a work group dedicated to sealing and guiding systems within PSPC Innov’Hydro (Structuring Project connected to the Competitiveness Hub). This project specifically brings together GE (...)

EN SAVOIR PLUS

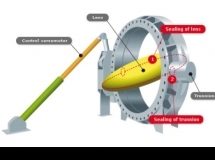

Success story : Sealing replacement on a butterfly valve

27/04/2015 - posted in PXL Seals

How could we have no leakage after one year of operation? This concrete case study describes the progress of a successful delivery which allowed obtaining outstanding results.One of the main suppliers of hydropower in France asked PXL SEALS to replace several seals on butterfly valve, located around (...)

EN SAVOIR PLUS

Should sealing be only designed considering material and geometry?

08/03/2015 - posted in Experience

Introduction Further to several customer experiences, we noticed that it is critical to work on both seal and housing parameters. This new way of considering projects is based on a specific experience: the replacement of a valve trunnion. The equipment working conditions caused big (...)

EN SAVOIR PLUS

CATEGORY

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |