News / Blog :

Butterfly valve seals : Seals that can sometimes be complex

What are the sealing solutions available for lenses and trunnions of butterfly seals (...)

READ MORE

Secure your hydro gates and valves with PXL HydroRubber

Hydroelectric plants, dams, gates : what are the existing sealing solutions ? (...)

READ MORE

Extend the life of your Kaplan turbines with PXL SEALS blade seals

How can the PXL SEALS sealing solution extend the life of your Kaplan turbines? The answer lies in a (...)

READ MOREHYDRO RANGE

Specific “HYDRO” range

For more than 30 years, we have been recognised as the experts in strategic sealing by hydropower players, major bearing manufacturers and industry - particularly in the naval, defence, oil & gas and construction sectors, internationally.

In the hydropower sector, we supply our seals and related services to our partners, both turbine OEMs and hydropower operators. Our references include companies such as ANDRITZ, CNR, EDF, EDP, GE, HYDRO QUÉBEC, KWO, RWE, UNIPER, VERBUND, VOITH and VORTEX HYDRA.

Drawing on this experience, we have developed a complete range of specific seals for the Hydro sector, designed to meet the technical requirements of critical applications.

The profiles and materials offered have been designed to meet the constraints associated to these hydropower strategic applications.

Generally speaking, these products are high accuracy with tight tolerances monobloc seals, without any adhesive bonding.

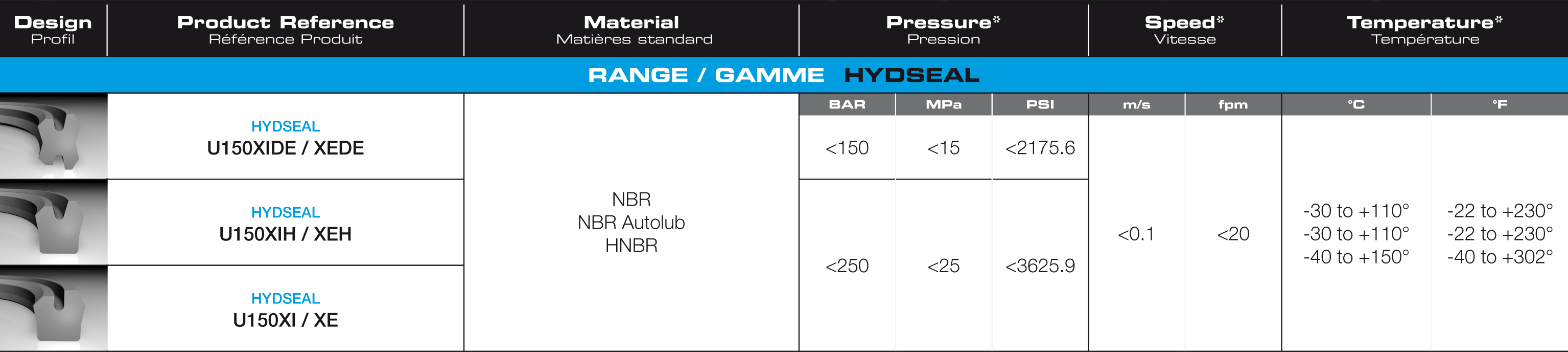

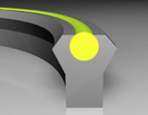

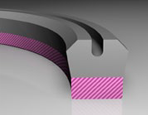

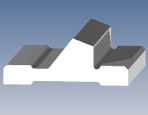

Seals for sealing blade trunnions of Kaplan turbines (horizontal or vertical): Dual-action HYDSEAL range

Developed in response to increasingly stringent constraints in terms of operating data and, in particular, cross-section variation data, these Hydro seals are suitable both as original equipment on new turbines and on renovated turbines.

This seal, which is a dual-action monobloc, is easier to fit and suitable for many sizes of housing. It is also extremely stable in the housing. It is generally accompanied by housing height compensation rings.

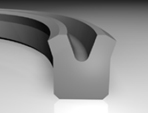

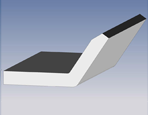

Seals for sealing guide vane trunnions and butterfly valve trunnions: DIRSEAL UNH range

These seals are designed to operate in a slowly rotating moment.

Taking its inspiration from a standard U-seal, the UNH profile has been specially tailored for guide vane trunnions by smartly combining the parameters comprising the seals, i.e. sizing of the seal and selection of the material quality. It may have to operate under occasionally substantial vibration conditions.

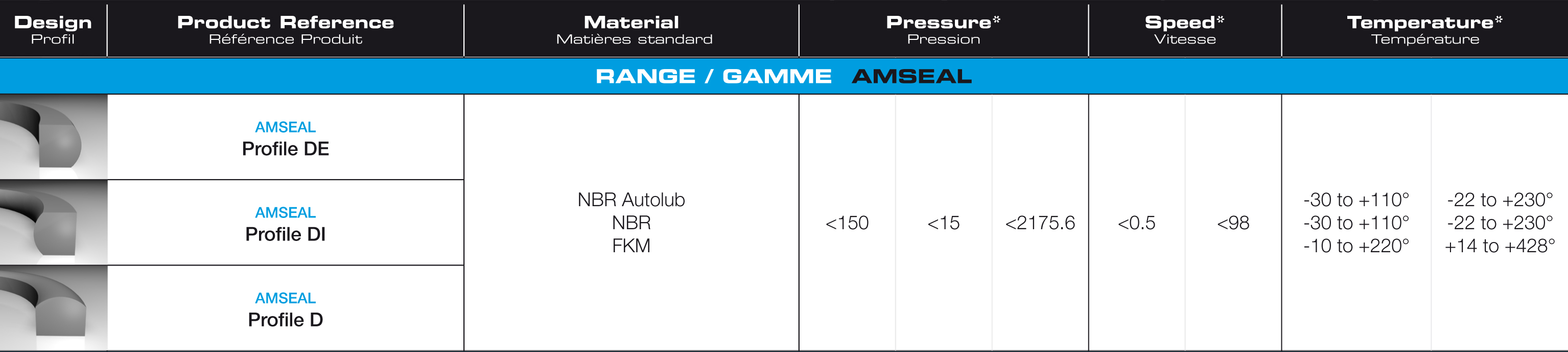

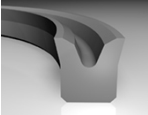

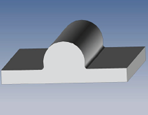

Seals for sealing the moving rings of spherical valves: AMSEAL range

Several profiles have been designed to withstand very different operating conditions depending on the equipment dimensions and working pressures, bringing about increasingly challenging cross-section variation conditions and extrusion clearances.

Other seals for hydro applications

Multi-purpose profiles are also available for all other applications designed and recommended in accordance with the data in the specifications: Servo motor seals, shaft seals, static, linear and scraper seals.

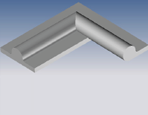

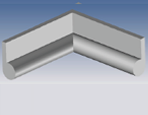

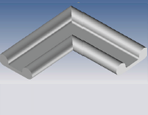

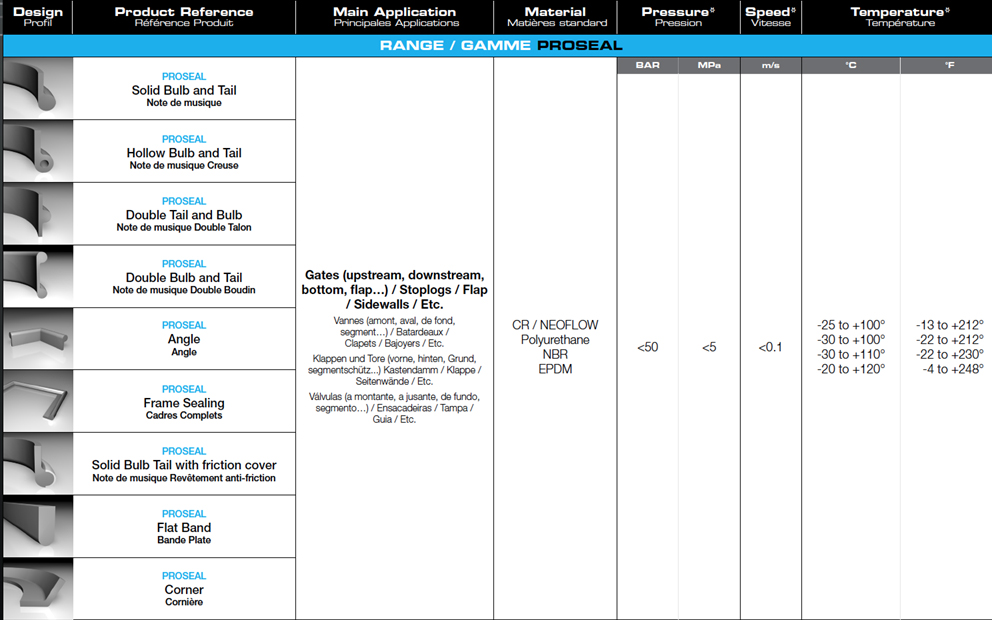

Floodgate seal

The following profiles were developed to ensure the sealing of floodgate seals installed in hydroelectric plants, dams and locks. This range, which is mainly produced by means of extrusion, is made from a high-quality, EPDM-based elastomer mix.

With its EPDM 70 base, PXL HydroRubber boasts excellent mechanical properties that are tested and verified in the laboratory.

In the field, it is the ideal solution for demanding specifications.

Its main characteristics are:

- Exceptional life span

- Good resistance to ozone

- Good breaking strength and tear resistance

- Limited impact on the environment

Discover the standard range of profiles we offer:

• Moulded corner units

PXL SEALS can also produce half-frames or full frames to equip any type of floodgate.

These frames are produced through the assembly of fully moulded corners and profile lengths. As far as possible, PXL SEALS carries out its assembly operations in its own workshops using its HLB process, thus avoiding any cold bonding, which is less resistant.

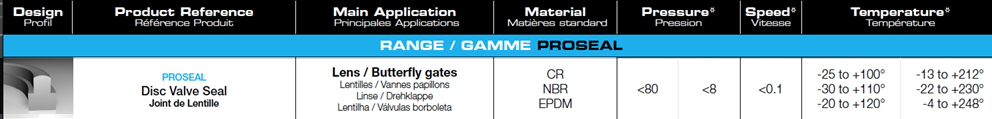

Seals for sealing butterfly valves

The PROSEAL range also includes lens seals. These key seals are sometimes difficult to adjust. PXL SEALS can offer an entire range of fully moulded lens seals that can go up to 7 metres in diameter.

PXL SEALS can also produce specific made-to-measure lens seals.

News / Blog :

Butterfly valve seals : Seals that can sometimes be complex

What are the sealing solutions available for lenses and trunnions of butterfly seals (...)

READ MORE

Secure your hydro gates and valves with PXL HydroRubber

Hydroelectric plants, dams, gates : what are the existing sealing solutions ? (...)

READ MORE

Extend the life of your Kaplan turbines with PXL SEALS blade seals

How can the PXL SEALS sealing solution extend the life of your Kaplan turbines? The answer lies in a (...)

READ MORE