News / Blog :

Butterfly valve seals : Seals that can sometimes be complex

What are the sealing solutions available for lenses and trunnions of butterfly seals (...)

READ MORE

Secure your hydro gates and valves with PXL HydroRubber

Hydroelectric plants, dams, gates : what are the existing sealing solutions ? (...)

READ MORE

Extend the life of your Kaplan turbines with PXL SEALS blade seals

How can the PXL SEALS sealing solution extend the life of your Kaplan turbines? The answer lies in a (...)

READ MORESEALS FOR INDUSTRY

From simply choosing an O-ring, to carrying out on-site assembly operations, to defining specific seals, either in static or dynamic assemblies, PXL SEALS is at your service to help you make the right decisions.

Rotary joints, feeders, actuators, hydraulic and pneumatic systems, valves, shock absorbers, engines, cryogenics, chemistry, mechanical seals and machine tools are just some of the applications we deal with.

PXL Seals’ seals for industry can be designed using the following materials:

-

PTFE, high-performance polymers, etc.

-

PU, PE, PVDF, PEEK, engineered plastics

-

NBR, FPM, EPDM, silicone, FFPM, etc.

-

PXLKOT, heavy-load composite materials

Some of our materials comply with the industrial sector’s general certifications: CE 1935/2004, FDA, ACS/KTW, 3A Sanitary Standards, USP class VI.

Discover the standard seals we offer:

- Dual-action seals

- HP seals

- Linear composite seals

- Scrapers

- U-seals

- Rotary seals

DUAL-ACTION SEALS

O-ring: The O-ring, which is the most commonly used profile for sealing, must be implemented according to best industry practice. We recommend the use of BAE from 70 bar, or even 40 bar in the event of a large clearance or significant temperature variation.

Profile D: An alternative to the O-ring, this is recommended in the case of high pressures or pulsed pressures. Its shape, above all, ensures a better fit and avoids kinking phenomena.

PB4: An alternative to the previous two, it is used in exactly the same way as the O-ring.

Its design makes it easy to position, and it reduces the contact surface while ensuring dual-action sealing.

A large selection of sizes, materials and hardnesses with certifications are available for these three profiles.

These profiles are mainly used in static or semi-static applications.

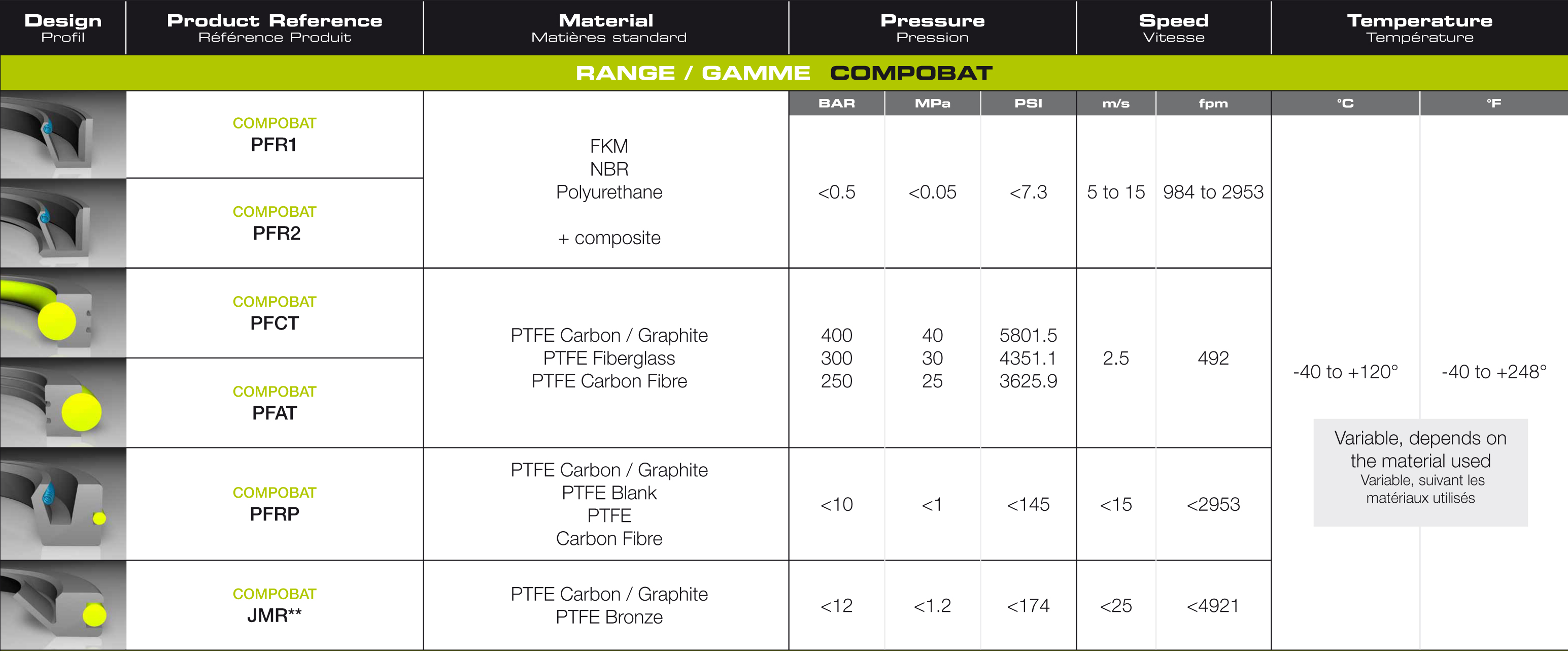

HP SEALS

Spring seals comprise a casing and a prestressing element. Generally made from PTFE, numerous other materials can be used according to the application (PE, PVDF, PEEK, PU, etc.).

Generally single action, but with the option for dual-action special profiles.

Designed to sit in standard AS568 grooves, these seals can be manufactured in most sizes.

- Wide temperature range: -200°C to +250°C (depending on the material used)

- Speed = 15m/s (or more depending on pressure and temp.)

- Pressure: 800 bar (or more, depending on geometry and material)

FT/FP

Execution with helicoidal strip spring

High seating pressure Suitable for high pressures, static Tolerates small movements at low speed

MT / MP

This seal is activated by a V-spring and can be used statically, mainly in a piston or rod assembly. It is fitted into open or semi-open groove through quick-release.

There is a silicone filling option for food or medical applications.

RT: Available in V or C form, this profile was developed for rotary or helicoidal movements. Its flange holds the seal in place.

It is fitted into an open groove only.

All of these profiles are available for use with standard housings, but they are also available on request for any size of housing.

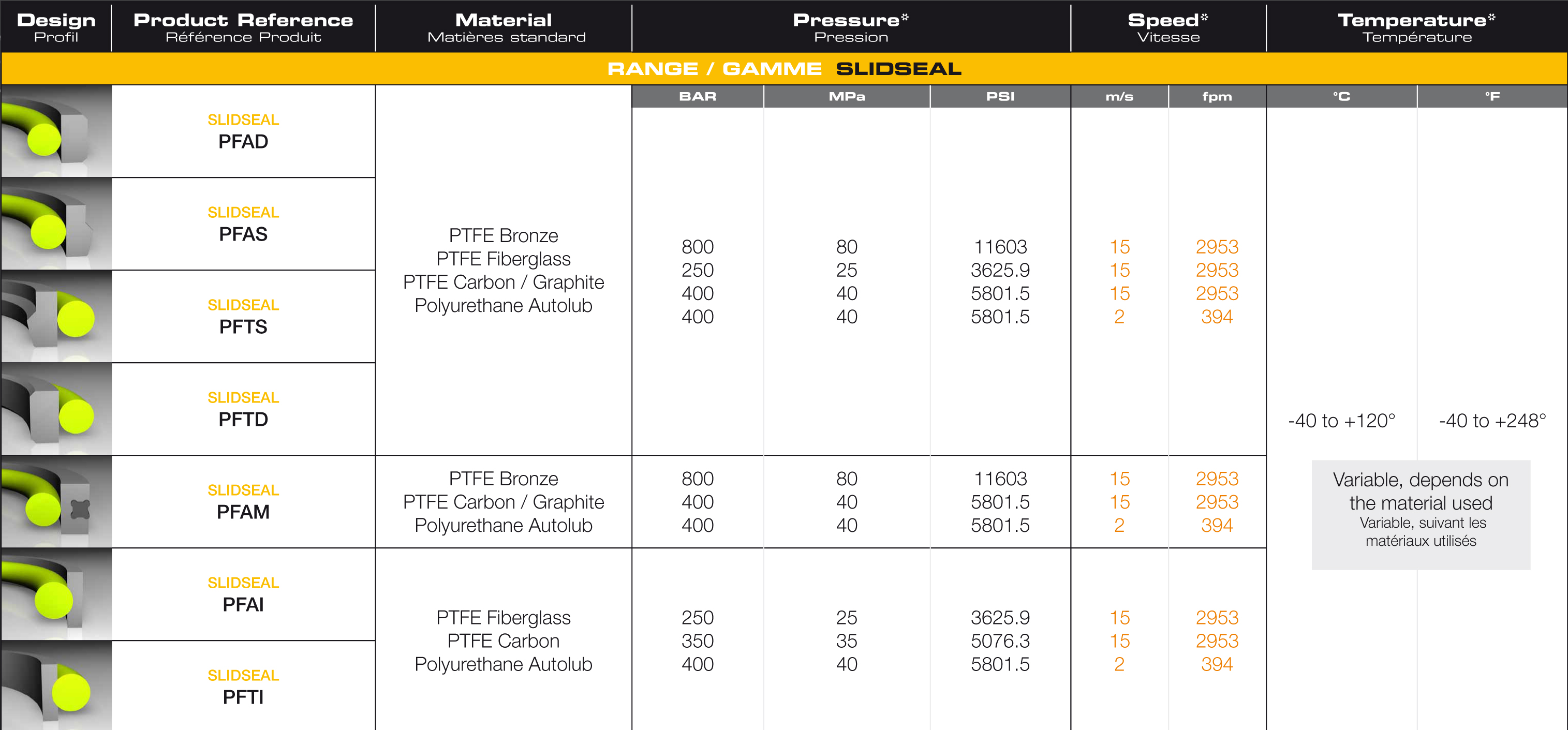

LINEAR COMPOSITE SEALS

Composite profiles work on the combination of an O-ring-type spreader and a pad made from a high-performance material (PU/PTFE/, etc.) for the friction level and extrusion resistance. These profiles allow very high pressure levels and operating speeds to be reached:

- Up to 400 bar (more for the special design)

- Up to 15 m/s (more for the special design)

They are either single action or double action and fitted into open or closed grooves. (Care should be taken with small diameters.)

Available in numerous material combinations, composite seals are suitable for a diverse range of applications:

hydraulic, pneumatic, food, etc.

PFAI/PFTI

This is the original version of the composite profiles. It is fitted into standard grooves for O-rings and decreases the friction and stick-slip level, as well as increasing the system’s extrusion resistance.

This is a good replacement for the O-ring + BAE combination.

PFAD/PFTD

Dual-action version which is commonly found in the

sealing systems of high-performance cylinders.

PFTS/PFAS

Single-action version, placed in series, which allows a thin film of oil to pass for lubrication purposes.

Many geometries are possible in order to best match the specific technical demand: high pressure, high temperature, low friction, low travel, dry running, high frequency, etc.

Composite seals must be combined with a guidance system (metal or by segments) to ensure that they function correctly.

It is essential that the surface of rubbing parts is kept in excellent condition, that the hardness is adequate and the fluid clean. (Our design office will help you choose the appropriate solutions to use.)

- Available in a rod or piston version.

- All of these profiles are available for use with standard housings, but they are also available on request for all sizes of housing.

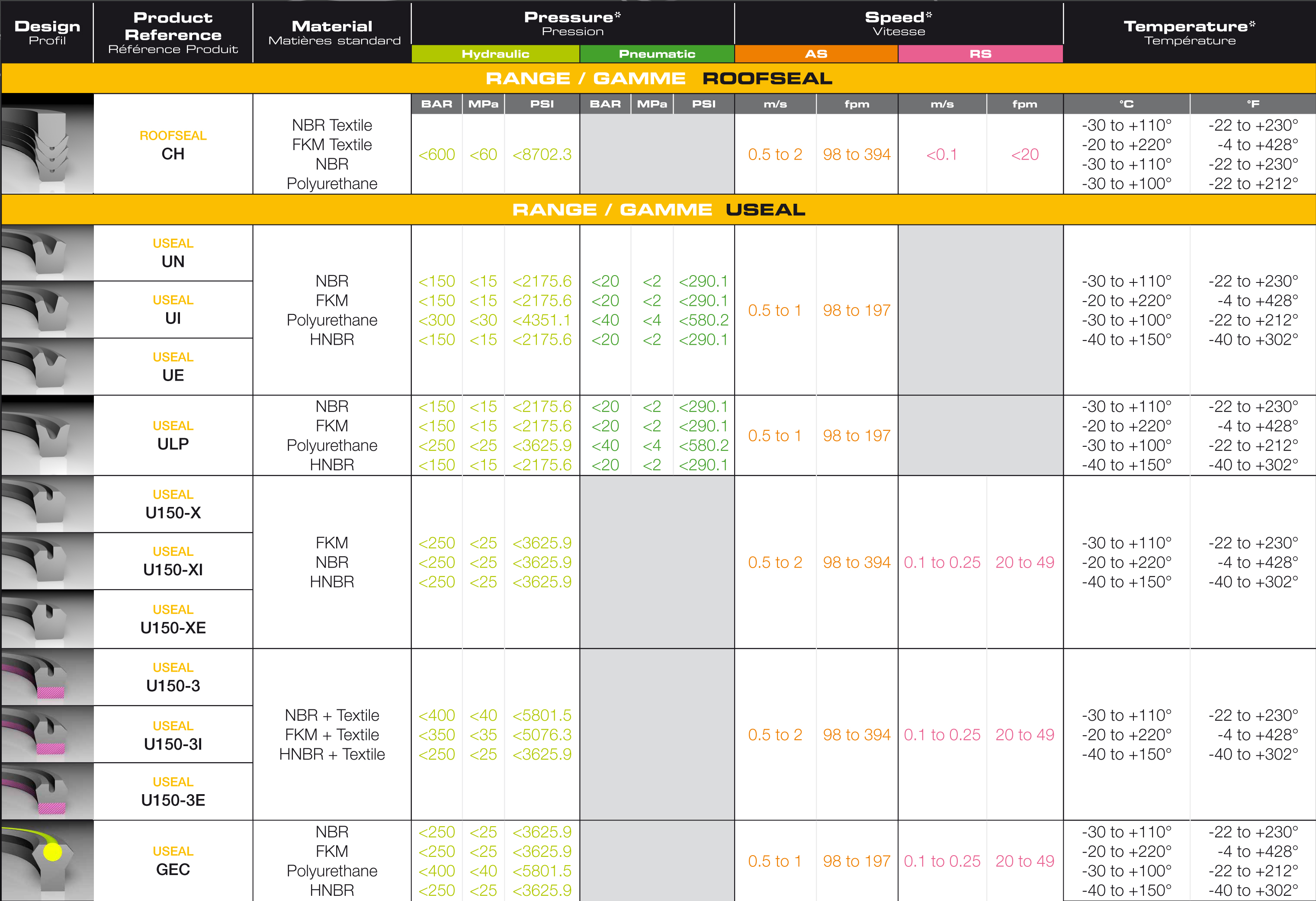

SCRAPERS

The choice of a scraper system is vital when developing an effective and reliable sealing system. Its main function is to prevent pollution (either solid or liquid) from getting inside the system and impairing its operation.

Also, it contains a film of oil preventing leaks towards the external environment. Numerous profiles are available in a wide range of materials to match your technical and economic requirements as closely as possible.

- Single-action scrapers are available and extensively used in hydraulic applications, for instance, but dual-action scrapers are also available and are the essential addition to single-action composite rod seals.

- Versions for boring are available for specific applications (food industry, fluid processing, medical).

Traditionally made of NBR or FPM, many variations are possible: EPDM, PU, PTFE, engineered plastics and other fabric versions. These are fitted into closed, semi-open or open grooves, depending on the type of scraper selected: flexible, with composite or metal cage or insert.

U-SEALS

Along with the O-ring, the U-seal is the most widespread profile in the sealing sector. These seals come in a multitude of different profiles and are used on a complementary basis to reflect the precise input data of your application (fluid type, temperature, pressure, etc.).

The broad range of materials and designs can be used to resolve issues relating to friction, extrusion, etc.

From ULP seals made from low-hardness elastomer and used for low-pressure pneumatic applications, to U150-XI H profiles made from high-hardness polyurethane, to U150-3 seals made from elastomer reinforced with fabric that can reach pressures of 400 bar, there is an installation solution for most applications and standard service conditions in the form of one or other of the U profiles. Naturally, all of these profiles are available in the rod or piston version with asymmetric lips to ensure that they match your requirements.

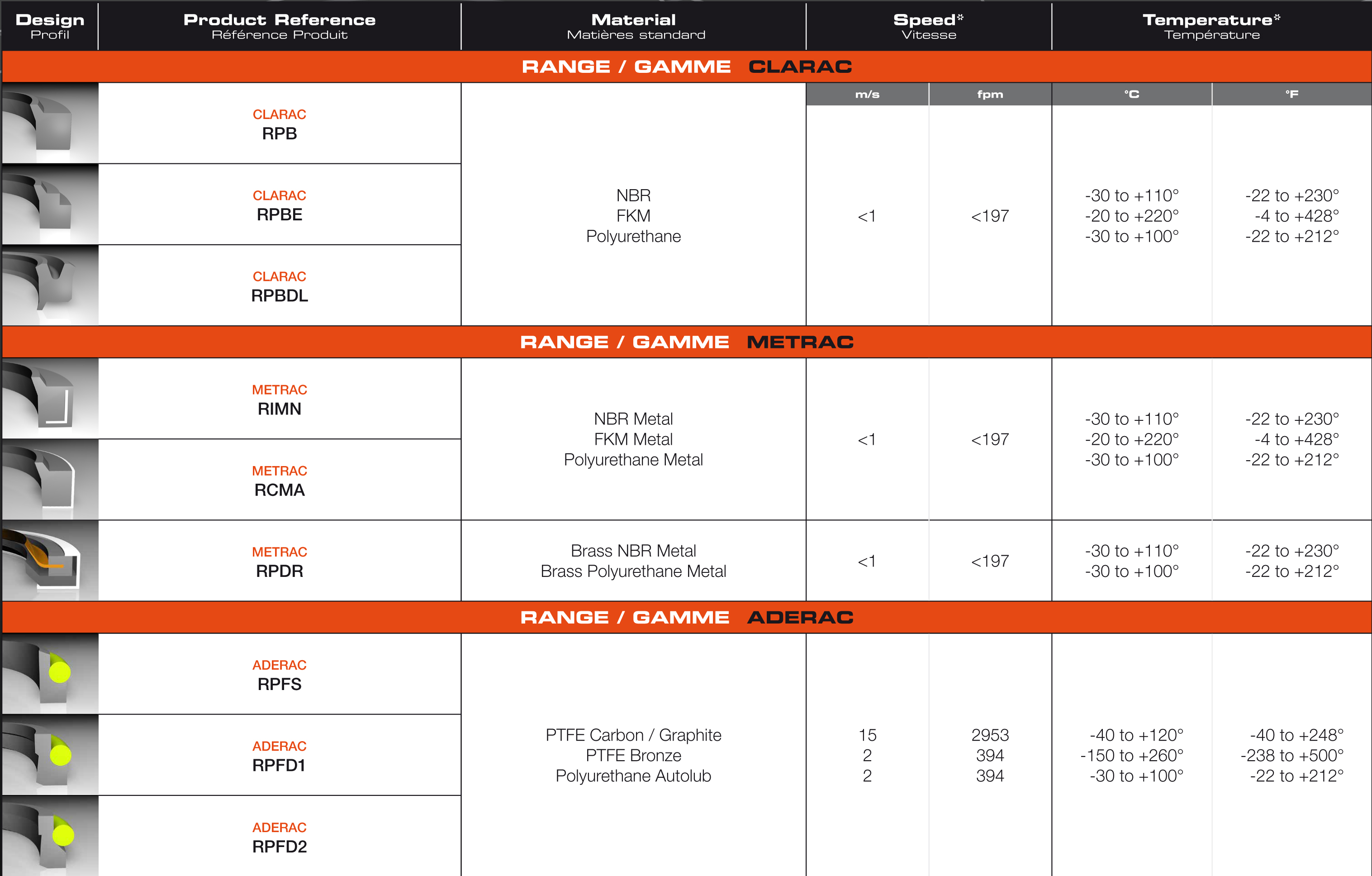

ROTARY SEALS

There are many profiles available depending on the application, pressure, temperature, fluids in contact and rotation speed.

For slow and irregular rotation movements, some of the profiles that have already been presented could be used (particularly U-seals or spring profiles).

For more demanding applications with high rotation speeds, different profiles can be used, also depending on the input data.

Lip seal rings:

In the high-performance rotary seals category, there is also a family of seals known as ‘lip ring seals’.

A very diverse range of profiles and materials can be used even in the most challenging conditions.

Rotary compact seals:

Just like linear composite seals, rotary composite profiles rely on the combination of a pad and a spreader. A broad range of materials can cater for the diverse range of applications encountered, e.g. hydraulic, pneumatic, food, etc.

These profiles allow very high pressure levels and operating speeds to be reached:

- Up to 400 bar (even more for the special design)

- Up to 2 m/s (even more for the special design)

- Temperature range from -20°C to +250°C (depending on materials)

Many geometries are possible in order to best match the specific technical demand: high pressure, high temperature, low friction, dry running, etc.

Composite seals must be combined with a guidance system (metal or by segments) to ensure that they function correctly.

It is essential that the surface of rubbing parts is kept in excellent condition, that the hardness is adequate and the fluid clean. (Our design office will help you choose the appropriate solutions to use.)

- Available in a rod or piston version.

- All of these profiles are available for use with standard housings, but they are also available on request for all sizes of housing.

We also manufacture facial seals, mechanical seals and V-rings, etc.

News / Blog :

Butterfly valve seals : Seals that can sometimes be complex

What are the sealing solutions available for lenses and trunnions of butterfly seals (...)

READ MORE

Secure your hydro gates and valves with PXL HydroRubber

Hydroelectric plants, dams, gates : what are the existing sealing solutions ? (...)

READ MORE

Extend the life of your Kaplan turbines with PXL SEALS blade seals

How can the PXL SEALS sealing solution extend the life of your Kaplan turbines? The answer lies in a (...)

READ MORE