News / Blog :

Butterfly valve seals : Seals that can sometimes be complex

What are the sealing solutions available for lenses and trunnions of butterfly seals (...)

READ MORE

Secure your hydro gates and valves with PXL HydroRubber

Hydroelectric plants, dams, gates : what are the existing sealing solutions ? (...)

READ MORE

Extend the life of your Kaplan turbines with PXL SEALS blade seals

How can the PXL SEALS sealing solution extend the life of your Kaplan turbines? The answer lies in a (...)

READ MORESEALING SYSTEMS FOR THE NAVAL AND MARITIME SECTORS

OPT FOR EXPERIENCE AND SAFETY

For more than 30 years, PXL SEALS has been designing and developing sealing solutions for the naval industry.

Seals for propulsion units (PODS), propeller shafts andship engines, bearings and slewing rings are particularly strategic because they are usually expensive to replace.That’s why they must be extremely reliable.

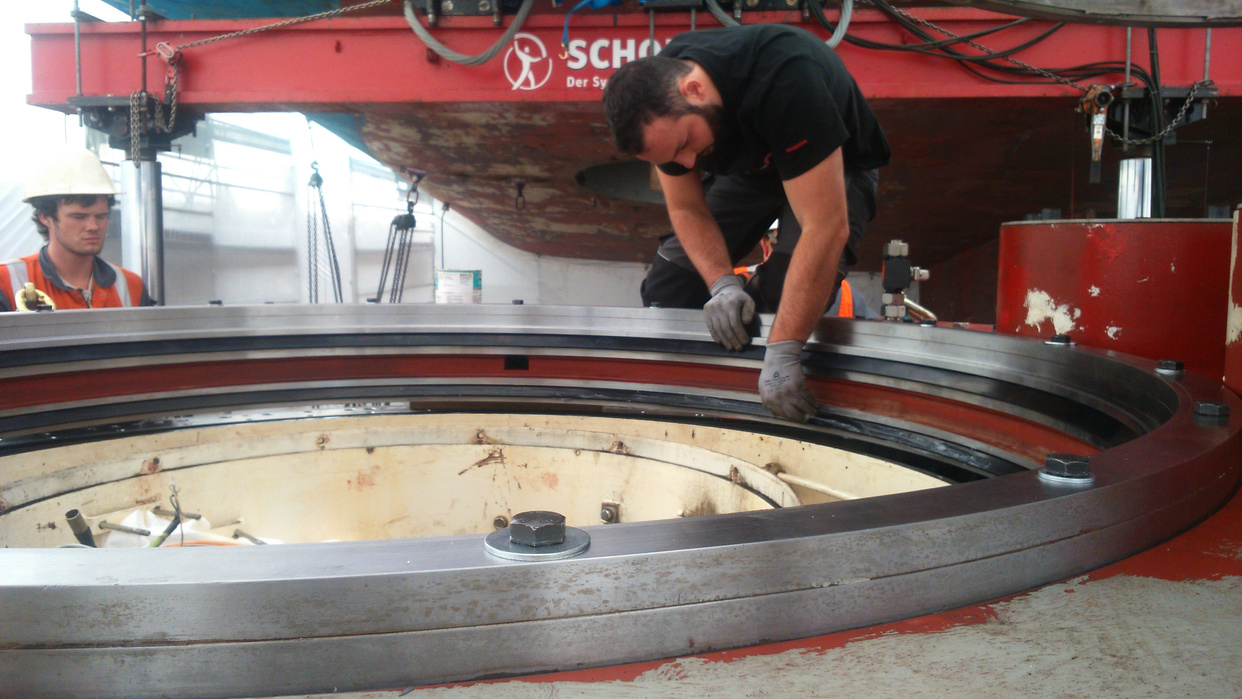

Our team can also work on site to fit and/or replace seals.

- The rotating rings can be supplied as split units so that they can be installed on site without dismantling the equipment.

- Large diameter slewing ring seals can be moulded onsite.

RANGES OF SEALS FOR NAVAL APPLICATIONS

PXL SEALS has a wealth of experience in sealing and elastomer processing and has become a key partner for major manufacturers.

Seals for the naval and maritime sectors sometimes have to meet the most demanding constraints, which must be considered in the design of the seals.

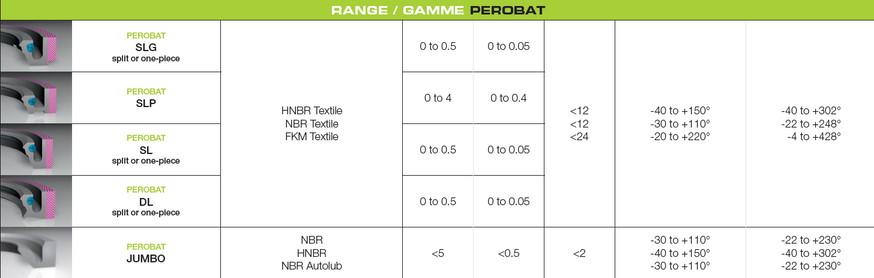

PEROBAT SEALS

Spring and lip seal rings

The PEROBAT range of rotary shaft seals from PXL SEALS, designed to operate on tracks in continuous rotary motion, covers a very wide range of diameters and can be made from different materials to suit the operating conditions.

These parts are available in several versions: single lip, double lip including an anti-dust seal, reinforced when there is pressure.

JUMBO seals

The PEROBAT range of rotary shaft seals from PXL SEALS, designed to operate on tracks in continuous rotary motion, covers a very wide range of diameters and can be made from different materials to suit the operating conditions.

These parts are available in several versions: single lip, double lip including an anti-dust seal,reinforced when there is pressure.

PXL SEALS is also able to design specific, made-to-measure products tailored to your specifications.

CASE STUDIES

Whether you need to replace a split lip ring or alarge-diameter seal, the PXL SEALS teams can support and advise you.

> SEAL FOR A SHIP GATE

OUR STRENGTHS

Responsiveness, presence, and commitment are the three values we all share at PXL SEALS, which is constantly adapting its teams to market constraints. We know how to be agile and how to guarantee a rapid response at all times.

Certified to ISO 9001 and 45001 standards, we place quality and our customers at the heart of our concerns.

DESIGN OFFICE

PXL SEALS provides its customers with more than 30 years' experience, recorded in technical databases, to help them find the best possible solution.

In specific cases, the design office uses calculation or control methods such as finite element digital simulation. Similarly, it may sometimes be necessary to accompany them with tests on a test bench to be conducted in its own laboratory or by its partners.

In high-stakes applications, PXLSEALS favours fully moulded solutions with tighter tolerances than other processing methods.

MANUFACTURING WORKSHOP

PXL SEALS manufactures most of its products in its Bellegarde-sur-Valserine workshop, so it controls the entire value chain, from solution design to delivery toits customers' sites.

ON-SITE INTERVENTIONS

PXL SEALS operates throughout France and, in the most strategic cases, also travels abroad to install or maintain the seals it manufactures and sells to its customers.

Our various on-site processes provide customers with“turnkey” solutions without dismantling the equipment,whether this involves simple assembly, bonding or moulding.

News / Blog :

Butterfly valve seals : Seals that can sometimes be complex

What are the sealing solutions available for lenses and trunnions of butterfly seals (...)

READ MORE

Secure your hydro gates and valves with PXL HydroRubber

Hydroelectric plants, dams, gates : what are the existing sealing solutions ? (...)

READ MORE

Extend the life of your Kaplan turbines with PXL SEALS blade seals

How can the PXL SEALS sealing solution extend the life of your Kaplan turbines? The answer lies in a (...)

READ MORE

.png)