ALL NEWS :

Butterfly valve seals : Seals that can sometimes be complex

19/11/2025

Butterfly valves or lenses, are control devices that allow flow to be directed to or away from a pipe or piece of equipment. They are found in many industrial sectors, particularly in hydroelectric power plants, where they are used to manage the flow of water from penstocks to turbines (Kaplan, Francis), as well as water drainage (level control, emptying).

They require reliable sealing systems to ensure proper operation and safety of the installation.

The main types of seals used in butterfly valves are as follows:

- lens seals, which provide peripheral sealing;

- trunnion seals, which seal the valve shaft.

In some cases, a connecting seal is also used between the valve body and the pipe.

Let's take a look at the constraints of butterfly valves in terms of sealing and the different types of seals available.

1. Specific features/constraints of butterfly valve seals

Comprehensive support, from design to operation

- Design and expertise: analysis of the existing solution on site and in the design office.

- Technical recommendations: delivery of a technical file including analysis of existing equipment and recommendations, 2D and 3D drawings, and drawings of parts to be re-machined with dimensions and machining tolerances.

- Manufacture of the sealing system: manufacture of molds (if necessary) or production of seals using existing tools.

- Assembly assistance: participation in dry assembly at the customer's workshop, adjustment and inspection of the seal to ensure uniform contact around the entire circumference of the valve body and a perfect seal.

PXL SEALS can work with operators to replace all or part of an existing lens seal. The seal adjustment made in the workshop must be finalized once the valve is installed in the pipeline.

Thanks to its unique expertise, PXL SEALS offers customized solutions, from molding to on-site installation assistance.

Let's now take a look at the sealing solutions available for lenses and trunnions:

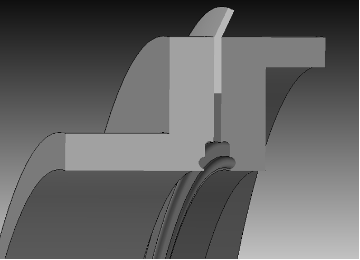

Butterfly valve with centered trunnions and bezel seal (monobloc between the lens and trunnion parts)

2. Types of valves

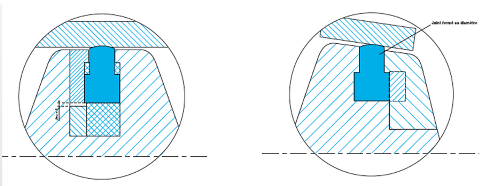

There are two scenarios: centered or off-center lenses. The sealing structure differs considerably between these two scenarios.

Butterfly valve with centered lens / Butterfly valve with offset lens

a. Off-center lens cases

In the case of butterfly valves with off-center pins, the lens seal is not affected by the presence of the pins and can therefore be monobloc. PXL SEALS designs and manufactures monobloc lens seals, molded without joints in its production workshops in Valserhône.

This technology guarantees optimal and consistent sealing, even on very large diameters.

Key benefits:

- Fully molded seal, without gluing or joints

- No size limitations (we have produced seals with diameters of over 7 m for this type of equipment)

b.Centered lenses

In the case of a butterfly valve with centered pins, we offer a high-quality molded seal delivered in length.

In this case, given the complexity of the connection between the lens seal and the pin seal, it will be necessary to make adjustments and modifications directly on the valve once the seals have been installed. Given the precision required for these operations, we recommend that you call on experienced technicians or our teams to carry them out.

3. Lens seals for butterfly valves

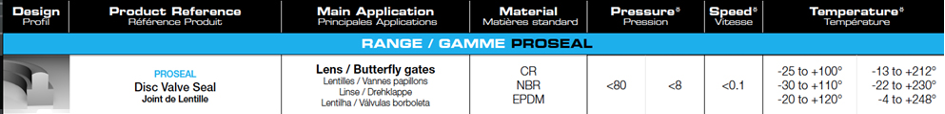

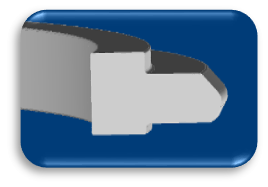

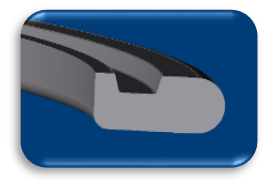

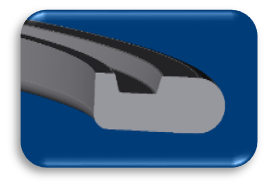

- Standard lens seals

Joint de lentille standard PXL SEAL

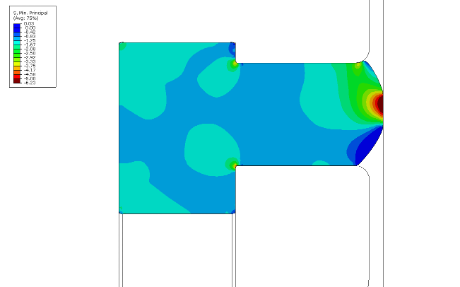

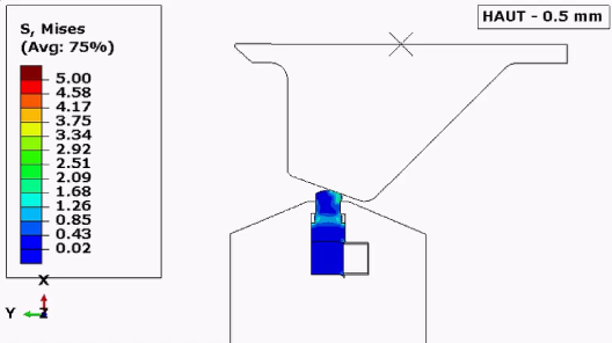

Simulation extract of a lens seal

- Other lens seals used

The profile shown in the previous section, although the most common, is of course not the only lens seal available. Depending on the original design of the valves, or in order to address specific operating issues, there are a multitude of seal profiles available, which is why we have a wide range of tools at our disposal.

From moulding to packaging, each stage is carried out under strict control:

- Quality control at each stage of production,

- Customised packaging to preserve the integrity of the seal until delivery

- Comprehensive technical support.

4. Butterfly valve spindle seals

For spindle seals, PXL SEALS offers a wide range of solutions adapted to the operating conditions and specific design of each valve. The seal usually consists of a combination of several seals: static seals between the bronze bushings and the valve body, dynamic seals between the bronze bushings and the pins, but also and above all seals between the bronze bushings and the lens seal, which are also considered dynamic.

While static seals are mainly composed of O-rings or D-profiles, dynamic seals can be made with a number of different solutions depending on the valve design: U-seals, chevrons, composite seals, elastomer rings, flat strips, washers.

In terms of materials, again, a wide variety is possible depending on the type of seal and the conditions of use:

- U-shaped seals: NBR, HNBR, PU, etc.

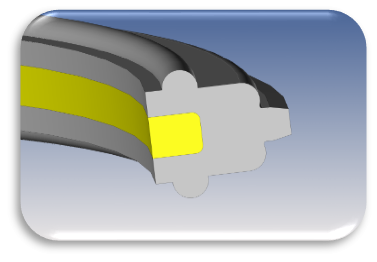

- Composite seals: combinations of high-performance materials such as polyurethane (PU), PTFE or polyethylene (PE) with NBR and HNBR.

- Chevron seals: made of textile NBR or polyurethane.

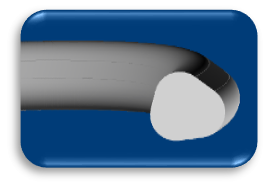

5. JB182 flange gaskets

Butterfly valve flange gaskets are installed between the valve body and the pipe. While these seals are sometimes provided by simple O-rings, in some cases they are provided by the JB182 gasket profile specifically developed by PXL SEALS.

This profile was developed to replace the old seals made from matted lead.

This profile consists of two separate parts, making it easy to install while ensuring the essential functions of this seal:

- Rigidity is ensured by the inner part

- The outer elastomer envelope ensures sealing and also gives the system flexibility and deformation capacity

Deployed at several sites, this new profile has proven its reliability and significantly facilitates installation, while eliminating the use of lead, which is no longer usable today for this type of function.

Check out the article JB182 profile for butterfly valve flange sealing

For any design, replacement, or maintenance requests, you can contact us at any time.

To learn more, discover some of our projects:

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |