News / Blog :

Butterfly valve seals : Seals that can sometimes be complex

What are the sealing solutions available for lenses and trunnions of butterfly seals (...)

READ MORE

Secure your hydro gates and valves with PXL HydroRubber

Hydroelectric plants, dams, gates : what are the existing sealing solutions ? (...)

READ MORE

Extend the life of your Kaplan turbines with PXL SEALS blade seals

How can the PXL SEALS sealing solution extend the life of your Kaplan turbines? The answer lies in a (...)

READ MOREGuide vane seals

In a hydroelectric plant, the guide vanes of Kaplan, bulb, or Francis turbines play an essential role.

The guide vanes located in this area regulate the flow of water feeding the turbine. Opening or closing them allows the hydraulic flow arriving at the turbine to be adjusted.

1) Specific features of guide vane seals

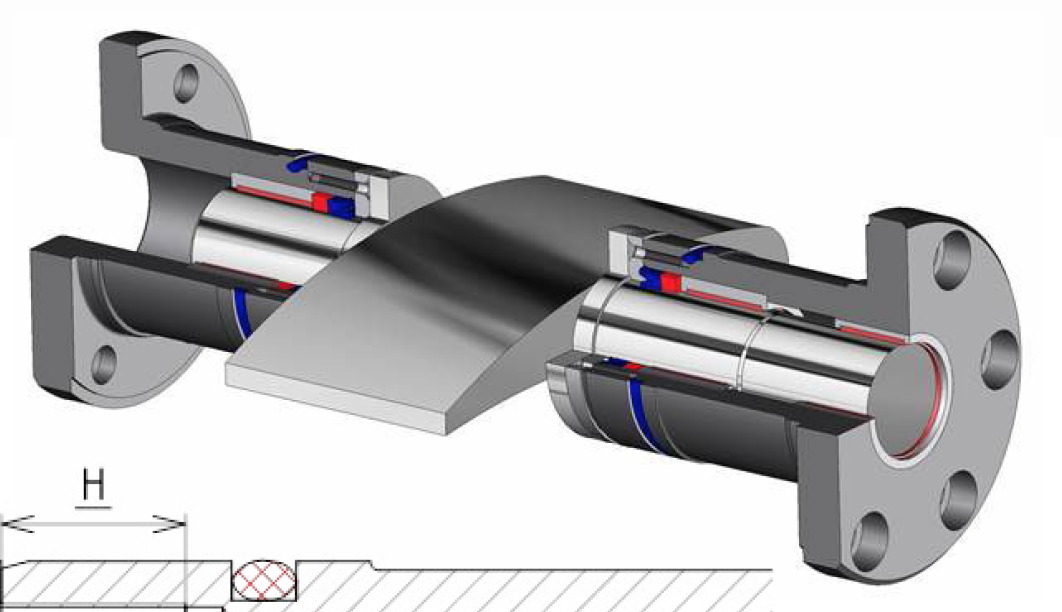

Guide vane seals are located at the guide vane journals. Their purpose is to prevent water from entering the guide areas.

Positioned around the journals, they ensure separation between the submerged parts and the internal mechanical areas.

These seals are subject to specific stresses:

- slow but frequent rotational movements,

- vibrations that can sometimes be significant depending on how the machine is operating,

- pressure and temperature variations,

- prolonged exposure to water.

Given these conditions, the reliability of the guide seals is crucial to ensuring the longevity of the guide ring and the efficient performance of the installation.

2) Available sealing solutions

a. Guide pot seals

These seals, generally ranging in size from Ø50 to Ø300 mm, ensure sealing around the trunnions.

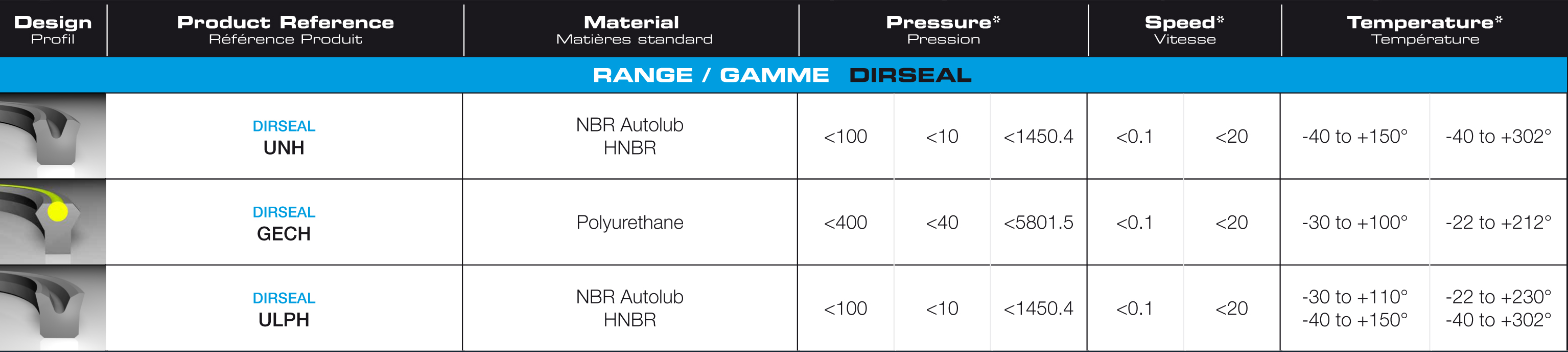

The most commonly used product is the UNH seal, from the DIRSEAL range developed by PXL SEALS.

UNH seals

Based on the standard U-profile, the UNH seal has been specially adapted for guide pins.

Its design is based on a balance between the precise dimensioning of the profile and the choice of the most appropriate elastomer material.

Features:

- Reliable operation at low speeds

- Vibration resistance

- Excellent durability

Made from self-lubricating NBR, HNBR, or polyurethane elastomer, it consists of two symmetrical lips, a heel, and a central groove ensuring stable positioning.

The assembly can be completed with an anti-extrusion ring.

While most applications involve sealing guide vanes, PXL SEALS also designs specific solutions for other areas such as guide vane tails.

Each configuration is custom-designed to meet the mechanical and hydraulic constraints specific to each project.

b. Guide vane tail seals

The seals positioned on the vane circle play a complementary role. They support the guide vanes when they are closed, limiting or eliminating water infiltration into the machine.

These systems can be combined with seals mounted directly on the guide vane and held in place by cover joints. They are then referred to as guide vane tail seals.

Unlike pot seals, these seals are not standardized: each project requires a specific study and design.

Different technologies exist depending on the type of turbine (Kaplan, Francis, or bulb) and the site constraints:

- Molded seals reinforced with metal inserts or overmolded on metal rails

- Polyurethane seals, offering excellent wear resistance

- Custom-made profiled seals made of elastomer or polyurethane

- Elastomer seals reinforced with metal inserts for areas subject to high stress

These solutions are fully customizable, both in terms of geometry and material formulation, to ensure perfect compatibility with the mechanical and hydraulic environment of each installation.

For specific cases, we can use CAD modeling to develop several variants according to requirements, thus offering a sealing solution that is perfectly suited to each turbine.

Additional information

For more information on guide vane seals, see also the article Guide vane seals: specific features and solutions.

Download the UNH technical data sheet

News / Blog :

Butterfly valve seals : Seals that can sometimes be complex

What are the sealing solutions available for lenses and trunnions of butterfly seals (...)

READ MORE

Secure your hydro gates and valves with PXL HydroRubber

Hydroelectric plants, dams, gates : what are the existing sealing solutions ? (...)

READ MORE

Extend the life of your Kaplan turbines with PXL SEALS blade seals

How can the PXL SEALS sealing solution extend the life of your Kaplan turbines? The answer lies in a (...)

READ MORE