ALL NEWS :

Guide vane seals: specific features and solutions

15/07/2024 - posté dans HYDRO

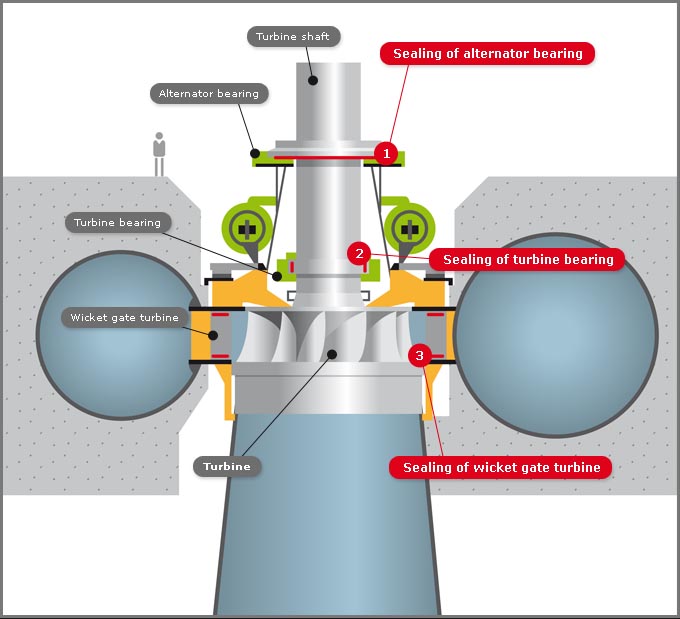

Of the various applications that require the use of seals at hydroelectric facilities, the distributors of Kaplan, Bulb and Francis turbines are the most important elements.

Guide vanes are devices present at hydroelectric facilities, in the zone called the distributor which allows for regulation of the water flow arriving at the turbine by opening or closing. This regulation is more or less broad and operational according to the design of the machine.

Are turbine trunnion blade seals used in this place? What types of seals are used? What are the particular features of these seals? What sealing solutions can we offer?

1 - What types of seals should be used for turbine Guide vanes?

There are several sealing zones linked to these guide vanes. The most common ones and the ones that we work on very regularly are the guide vane seals. These are seals located at the level of the trunnion blades and which are intended to prevent water from entering the guidance area.

While in most cases the seals involved are mainly those of the guide vane seals, we can also design and make specific seals that can appear in certain facilities.

This is the case in particular for seals which are sometimes installed in the “tails” of guide vanes.

2 - Seals for guide vanes

These seals are small (about Ø50 to Ø300).

The solution commonly used for making these seals is the UNH seal, a profile that was specifically adapted for this application.

In some particular cases, we can also provide other types of products, according to our customers’ specific needs.

The Guide vane must be dismantled in order to replace this seal.

The UNH seal, specially designed for the seals of guide vanes

Taking its inspiration from a standard U-seal, the UNH profile has been specially tailored for guide vane trunnions by smartly combining the parameters comprising the seals, i.e. sizing of the seal and selection of the material quality.

- This seal is designed to work in a slow rotating momentum.

- It can operate in high vibration conditions.

Technical features and materials

It is made of autolube Nitrile NBR or HNBR elastomer material, and is composed of two symmetrical lips, a heel and a central groove.

In the event of an extrusion gap greater than 0.5 mm and/or in the case of high pressures, an assembly with an anti-extrusion ring is possible.

Download the sheet for more technical information.

Seals for sealing guide vane trunnions and butterfly valve trunnions: DIRSEAL UNH Line

- Lèvre =Lip

- Gorge = Groove

- Talon =Heel

Seals for guide vane tails

The seals installed on the distributor and on which the Guide vanes press during the closing phases, thereby allowing the reduction or elimination of water entering the machine.

These seals can be supplemented with other seals which are placed on the Guide vane itself and maintained with seal covers. These are the so-called “guide vane tail” seals.

These latter two types of seals are more specific: no standardized solution exists and the solutions differ greatly from one project to another.

For the sealing of distributors on all types of turbines in hydro Kaplan, Francis or Bulb, PXL SEALS uses several solutions and technologies:

Molded seals reinforced with metallic inserts or seals overmolded on a metallic rail

Polyurethane seals

PXL SEALS can provide you with the most varied products to meet your particular needs. Whether for simple elastomer profile seals, polyurethane profiles and also elastomer seals reinforced with metallic inserts, we can provide you with the seals best suited to your application and your needs.

Custom seals for Guide vane tails

CAD visuals of 3 “variants”

For these 2 profiles, a metallic part (insert or envelope) is associated with the elastomer. The system for making these parts is specifically designed to allow for the holding of the metal parts during the molding process in order to obtain the desired finished parts.

NBR + metallic insert

NBR + metallic rail

PU seals

The PXL SEALS design department can also handle any requests for specific seals to meet its customers’ needs.

Don’t hesitate to contact us as of the planning phase of your project in order to define the solution which will be best suited in terms of manufacturing, installation and efficacy.

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |