ALL NEWS :

Secure your hydro gates and valves with PXL HydroRubber

08/09/2025 - posté dans HYDRO

What are the sealing solutions for steel-framed gates at hydroelectric plants, dams, and locks?

These gates play an essential role in the safety, operation, and performance of hydroelectric structures. Their seals are subject to mechanical, hydraulic, and environmental stresses and must meet high standards of reliability and durability.

PXL SEALS has many years of experience supporting operators and maintenance teams by offering innovative, tailored sealing solutions. One such solution is our EPDM HydroRubber compound, a robust, environmentally friendly material specially developed for valve seals that complies with DIN 19704, the industry benchmark standard.

1. Meeting the constraints of structured gates

PXL SEALS has been providing comprehensive solutions for various types of structured gates, including segment gates, lift gates, roof gates, wagon gates, cofferdams, and flap gates, for many years.

What are the challenges of valve seals?

Often considered "negligible" because they are obtained by extrusion, these seals are actually a major challenge.

- Depending on the type of valve, they are not always easy to replace. They are exposed to the elements and the presence of abrasive solids (sediment, dead wood, stones, etc.), so they can easily become damaged.

Optimizing mechanical properties is therefore a major challenge for users. - Connection areas (bonded joints) are also critical areas, as they can lead to leaks, torn seals, etc.

For all these reasons, we present here the solutions and products offered by PXL SEALS to best meet your expectations.

2. Profiles Designed for framed valve Seals

To meet user requirements, PXL SEALS offers a dedicated range of structural valve seals.

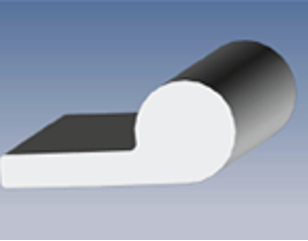

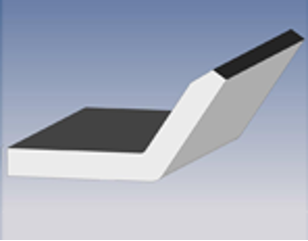

We have a wide selection of profile dies, ranging from standard shapes like music notes, flat strips, and angle irons to highly specific profiles. We also develop profiles tailored to our customers' needs. We can supply any profile type according to your needs.

Musical notes (hollow, solid) - Angle bars, flat strips - Special profiles

Browse our selection of profiles. These profiles are obtained by extrusion, and the manufacturing tolerances are in accordance with ISO 3302-1-E2. A table of values is available upon request.

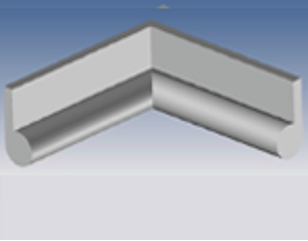

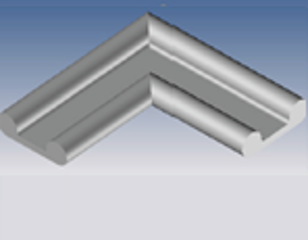

Toolings for framed gates seal manufacturing

3. EPDM HydroRubber Compound

We can offer a wide range of materials to meet your specific requirements. However, due to the primary constraints of these seals, we primarily offer our EPDM HydroRubber compound. This compound has been specially developed and tested for these applications.

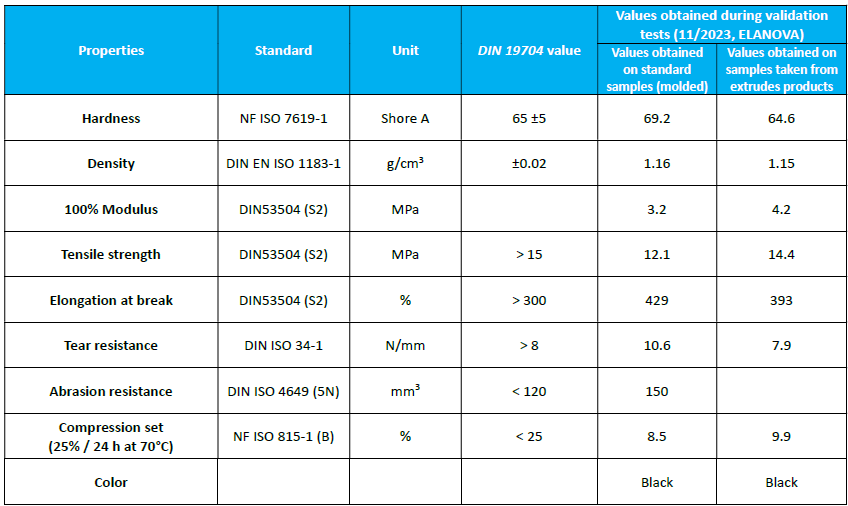

The compound has been tested in a laboratory to validate its compatibility with DIN 19704, the reference standard in waterproofing for steel valves.

A summary of the values obtained for our compound is provided below.

Advantages of PXL HydroRubber:

- Meets the specifications of the main players in the hydroelectricity sector (DIN 19704)

- Offers exceptional durability in water and outdoors (good ozone resistance).

- It has a limited environmental impact and respects the aquatic environment. Unlike polychloroprene compounds used in the past, it has no toxic emissions and does not have a significant environmental impact.

- It has excellent resistance to breakage and tearing.

4. Corners, Frames, and Connection Methods

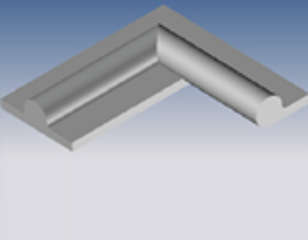

In addition to supplying profiles in various lengths, PXL SEALS offers finished or semi-finished corner blocks and frames.

- Molding corner blocks: Using molded corner blocks, when possible, avoids the need for cold bonding at 45° in corners. These areas tend to be subject to stress, with a high risk of bond failure.

Furthermore, these joints are not always easy to make, especially for slightly unusual profiles, right angles, and single-note angles connected to double-note angles.

These blocks can be delivered with extruded products to allow you to create joints on-site in straight areas. This method is much easier and more reliable.

We currently have a wide range of blocks in stock and can produce new ones to meet your specific needs.

A few examples of molding corner blocks

- We offer half and complete frames as genuine turnkey solutions that facilitate assembly, reduce the number of joints that need to be made on site (often in difficult conditions), and ensure the joints are more reliable.

We can supply different types of frames according to your needs, the type of profiles, and the valve. We recommend supplying half-frames with extra length that can be adjusted on site. This allows you to adapt exactly to the actual valve, which may differ from the plans. - Most PXL joints are made using cold or hot bonding (HLB) depending on the circumstances (joint area, tools, profile type, frame design, etc.).

When manufacturing our frames, we use a hot bonding process with material addition (HLB).

In certain cases, PXL SEALS uses the HLB ("Hot Layer Bound") process, which was developed by our design office. This process does not require glue and provides superior results compared to cyanoacrylate bonding.

You can join directly at a 45° angle instead of using cold bonding. The extruded profiles are joined using a mold. Alternatively, the joints are made between molded angles and extruded profile lengths.

Depending on the type of profiles and the shape of the frame, one method or the other is used.

The frames are made from PROSEAL profile extrusions.

PXL SEALS has a large inventory of standard items and can also design profiles with specific dimensions.

4 - Expertise and replacement of complete frames on the customer's site.

In addition to supplying finished or semi-finished profiles and frames, PXL SEALS can work on-site to adapt seals to equipment and carry out bonding. In this case, we can only carry out cold bonding.

- Expertise and adaptation of solutions based on the technology and initial design of the valve.

When replacing a structural valve seal, adaptation to the terrain, technology, and initial design of the valve is necessary. To determine the best solution, it is sometimes useful to visit the site and check for potential areas of weakness and risk of leakage. - Installation and adjustment of valve frame seals

PXL SEALS teams can assist with installing your valve frames on site when necessary. We can also cut to length, glue, and drill holes. See the possibilities, depending on the type of installation and our availability. - Adjusting or shaping parts.

Sometimes, it is necessary to "shape" parts to adapt them to the structure because this cannot be done directly on the manufactured part. Extra thickness can then be applied to the part in question to allow for these adjustments.

By choosing PXL SEALS and its HydroRubber range, operators are guaranteed a proven, environmentally friendly, sustainable solution that can withstand the most severe constraints of framed valves.

With expertise in design, manufacturing, and on-site interventions, PXL SEALS offers more than just seals—it offers a comprehensive, reliable, turnkey solution that guarantees performance and durability.

Opting for PXL SEALS' valve sealing solutions means choosing safety, reliability, and time savings thanks to simplified installation and reduced risk of leakage.

Contact us for more information on framed valve seals.

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |