ALL NEWS :

JB182 Profile for butterfly valve flange seal

29/03/2018 - posté dans HYDRO

At PXL SEALS, heavy-duty seals have been the bread and butter of our engineers and technicians for decades now, as they continually search for powerful and innovative solutions to meet the needs of our customers and track down together all of the leaks adversely affecting the operation of equipment.

This work has resulted in our teams having just jointly developed a new flange seal, to successfully replace the “lead seal” of the butterfly valve flanges.

Step forward, the “JB182” seal!

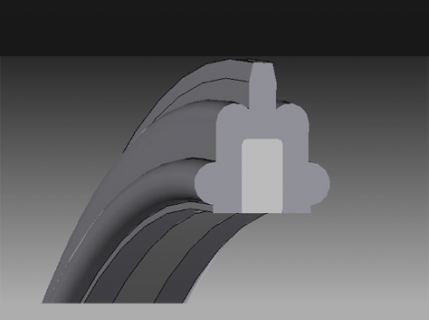

This new profile ensures the static sealing between penstocks and valve bodies. On old installations, the groove that is very often created in this location has a highly specific design (see simplified diagram below), in that it is machined into both the valve body and the penstock itself.

Until now, sealing was achieved by caulking a lead part. This prevented any liquid passing by filling the groove.

Since then, our understanding has moved on: the new standards forbid or restrict the use of lead. It was owing to these problems that we decided to design a special seal to fit this particularly complex housing.

The challenge: designing a suitable seal to replace the lead in the penstock/valve body joint

The originally devised groove allowed the lead to be held between the two parts to seal. However, although this design was so suitable with this material, it proved extremely problematic to replace the seals with safer materials during numerous maintenance operations. As well as this problem, there is also the issue that only a very low axial displacement is possible between the valve body and the penstock.

Replacement therefore very frequently entails having to modify the grooves (but this is difficult to perform on the penstock part because it is sealed in the building structure).

Therefore, the only option left was to develop an individual seal suitable for this complex housing.

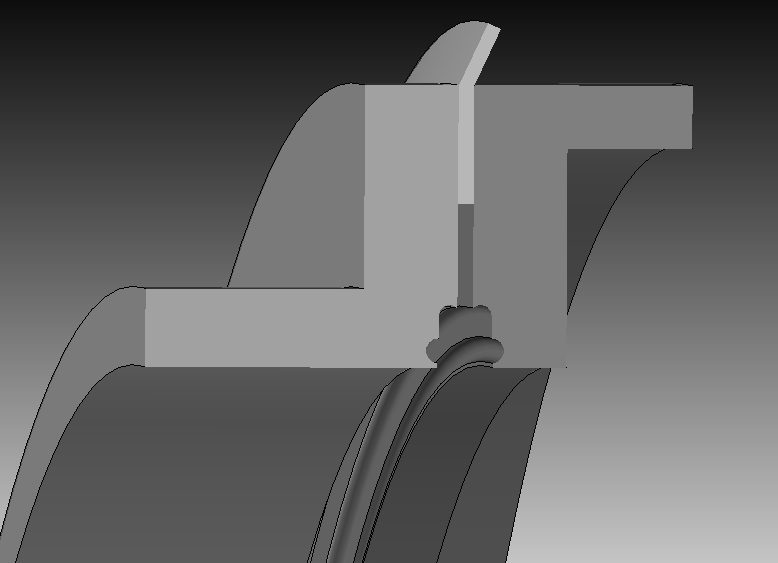

The solution: the JB182 dual-component seal

The JB182 seal rises to this technical challenge by using a “dual-component” solution which, thanks to the very different properties of these two components, provides both the required rigidity and clamping. Because of the properties it has owing to its composition, the elastomer outer casing enables this seal to perform its sealing job.

Each and every day, this new profile installed on several sites reconfirms its reliability and the fact that it satisfactorily addresses the fitting problems associated with the old profile. Moreover, it allows us to stop using lead.

If necessary, do not hesitate to contact the PXL SEALS technical department. Its team will examine all your individual requirements to propose the most suitable seal for your application.

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |