ALL NEWS :

Punt Dal Gall

01/06/2017 - posté dans HYDRO

Designing obturator sealing system to renovate guard gate and protect contributors: This was the challenge that PXL SEALS took up, on the impressive Punt Dal Gall dam.

Which were the main steps to handle this project successfully?

Discover how PXL Seals designed, manufactured and installed the sealing system on-site, fulfilling the project obligation and risk.

Dam's valves and gates are regularly checked and renovated to ensure the effective operation and safety.

Further to the successful Hongrin-Leman obturator project, Hydro Exploitation asked PXL SEALS to help them managing in this huge, new project.

Project: Obturator seals for Punt Dal Gall dam.

Tasks:

- Huge sealing system

- Obturators installation by scuba divers (120m depth)

- Contributor working behind the obturators

- Limited bulky items

- 40mm unevenness

- Difficult planification

PXL SEALS solution:

The developed seal is in direct contact with the dam structure (on concrete). On that structure, it may have up to 40mm of unevenness : the sealing system must be able to fill this unevenness.

PXL SEALS followed the below steps to design and validate his sealing profile :

Sealing design:

PXL SEALS worked with the partners to determine the requirements specification: bottom outlet obturator seal and baseplate obturator seal.

For economic reasons, the team decided to develop one single seal for both obturators (same issue).

To design this seal with its constraints (unevenness, bulk, etc.). PXL SEALS has been using its expertise and experience on this kind of project and its material knowledge for hydro seal.

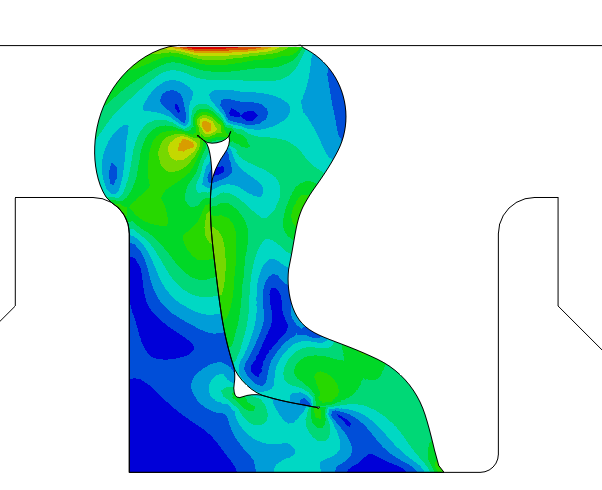

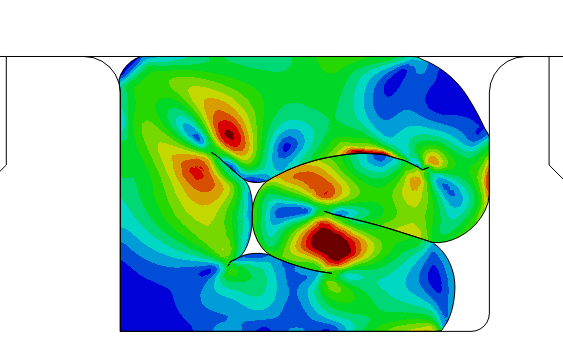

Finite element analysis and test:

Once the seal design was done, PXL SEALS simulated the behaviour with FEA and bench test.

The final design is validated, once all FEA and tests have succeeded.

Manufacturing and on-site installation:

After manufacturing the seal by extrusion, PXL SEALS installed them on site on both obturators.

PXL SEALS succeeded in this project: no leakage on bottom outlet and baseplate obturators.

Punt Dal Gall project was very successful for PXL SEALS and all partners.

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |