ALL NEWS :

Success story : Sealing replacement on a butterfly valve

27/04/2015 - posté dans PXL Seals

How could we have no leakage after one year of operation? This concrete case study describes the progress of a successful delivery which allowed obtaining outstanding results.

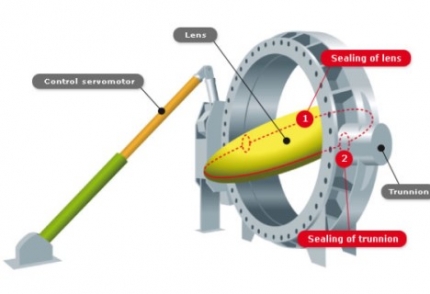

One of the main suppliers of hydropower in France asked PXL SEALS to replace several seals on butterfly valve, located around trunnions and lens.

This was the complete service proposed :

The sealing study and the on-site expertise highlighted two important points:

The study and the expertise resulted in the optimal sealing solution. The dimensional measurements identified the minimal and maximal housing values to develop customized seals.

Using a theoretically plan is very important but the objective must be realistic and as close as possible of realities grounds taking into account the housing geometry.

Then, seals have been shaped to allow an optimal contact between t trunnion and lens seals.

The PXL SEALS ON-SITE Team know-how, together with a close collaboration with the customer and with the perfect seals control - study, on-site expertise, manufacturing and installation – led to a very good result: 0,25 liters / minute of leak rate after the requalification!

The customer’s technical team greeted the collaboration with PXL SEALS and the obtained results.

BACK TO NEWS

One of the main suppliers of hydropower in France asked PXL SEALS to replace several seals on butterfly valve, located around trunnions and lens.

This was the complete service proposed :

- A Sealing Technical study realized together with the customer

- An on-site expertise

- Seals’ manufacturing

- Implementation, adjustment and forming of the seals on-site

The sealing study and the on-site expertise highlighted two important points:

- There was an issue with the seals’ housing dimensions on the lens. We needed to re-process and obtain a housing in accordance with the seals operating.

- Some recommendations were given regarding the surfaces states to guarantee an efficient sealing

The study and the expertise resulted in the optimal sealing solution. The dimensional measurements identified the minimal and maximal housing values to develop customized seals.

Using a theoretically plan is very important but the objective must be realistic and as close as possible of realities grounds taking into account the housing geometry.

Then, seals have been shaped to allow an optimal contact between t trunnion and lens seals.

The PXL SEALS ON-SITE Team know-how, together with a close collaboration with the customer and with the perfect seals control - study, on-site expertise, manufacturing and installation – led to a very good result: 0,25 liters / minute of leak rate after the requalification!

The customer’s technical team greeted the collaboration with PXL SEALS and the obtained results.

CATEGORIES

Events

Experience

High-technology industries

HYDRO

Large bearings

MD WAY

On-site services

PXL Seals

Success stories

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |