ALL NEWS :

Sealing systems for shipbuilding / repair and the maritime sector : opting for safety

10/06/2022 - posté dans Large bearings

As PXL SEALS is specialized in strategic seals, we also design, manufacture and install seals for the shipbuilding/repair and the maritime sector.

More specifically, we equip PODS, boat engines, shaft lines and all the components installed on the periphery of these equipments.

The PXL SEALS sealing systems for shipbuilding/repair and maritime sector are a perfect barrier preventing any pollution of sea water by the oil or grease contained in the mechanical parts and avoiding the introduction of water inside the systems.

The PXL SEALS range goes from standard to customized requiring a specific study and an adapted design. We also install and provide on-site refurbishment services.

Rotating shaft seals

PXL SEALS' rotating shaft seals called “PEROBAT” have been designed to operate on tracks in continuous rotary motion. This range covers a very wide diameters ranging and can be made from many different materials according to the operating conditions.

Rotating shaft seals are available in several versions : single lip, double lip including an anti-dust shaft seal, reinforced when there is pressure.

PEROBATS are closed when assembled during the 1st assembly and are then available in their divisible version to facilitate the on site replacement, without needing to dismantle the equipment.

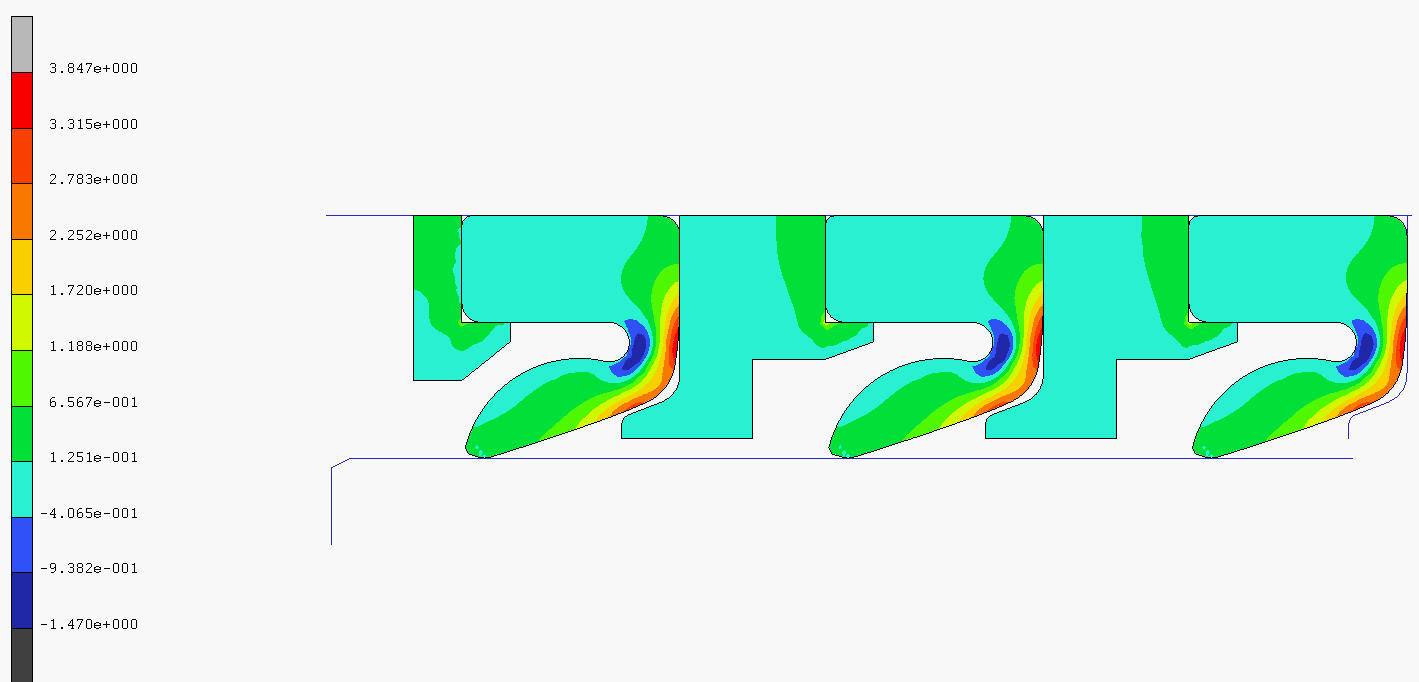

FEA of PXL SEALS' Perobat Jumbo seal

PODS slewing ring seals, constraints and challenges

The PEROBAT JUMBO seals installed on PODS slewing rings are designed to operate on tracks in slow rotary motion and must make it possible to take up eccentricities or variations in section, often significant, linked to the movement of the parts relative to each other.

In terms of sealing, these seals are designed to operate at low pressure or even in the absence of pressure.

For these strategic needs, the manufacturing process developed by PXL SEALS makes it possible to produce seals from large diameter to very large diameter (without any limit), fully molded, one-piece (according to ISO 3302-1-M2), guaranteeing constant mechanical properties over the entire circumference of the joint as well as tight dimensional tolerances.

PXL SEALS does not use extruded products, which are less precise (according to ISO 3302-1-E2) and require cold or hot bonding by adding glue.

We use approved transformed raw materials, tested in laboratory, compatible with most oils and greases used in bearings.

Replacement and maintenance of slewing ring seals and PODS

The MD-WAY® process developed and used by PXL SEALS makes it possible to produce joints molded on site and thus to replace seals without dismantling the equipment. This solution offers guaranteed reliability, equivalent to that which would be obtained with a joint that is entirely molded in the workshop. Seals obtained using the MD -WAY® method are more resistant than any other solutions obtained by cold butting, or even hot bonding with the addition of glue.

Replacement of PODS' seals using MDWAY® patented method

Opting for security

Seals for PODS, boat engines, bearings and slewing rings, used the shipbuilding/repair, naval and maritime sectors are particularly strategic, because their replacement is generally very expensive, and must therefore be extremely reliable.

PXL SEALS has implemented processes adapted to the challenges of this sector. It is one of the only companies to offer fully molded seals, both for original equipment and for maintenance.

Read more about an example of design and installation of seals for ship gate.

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |