ALL NEWS :

Framed gates sealing: what solutions for making valve frames?

22/05/2022 - posté dans HYDRO

Among the many strategic seals in hydropower applications, PXL SEALS has been working for many years on the ever more complete supply of seals intended for the different types of framed gates, and in particular the seals for segment gates, wagon gates, cofferdams and flap valves.

PXL SEALS offers sealing systems for both Original Equipment Manufacturers of valves (OEM ) and operators or mechanical companies in charge of the maintenance of these valves (MRO).

Valve frame seals to facilitate assembly

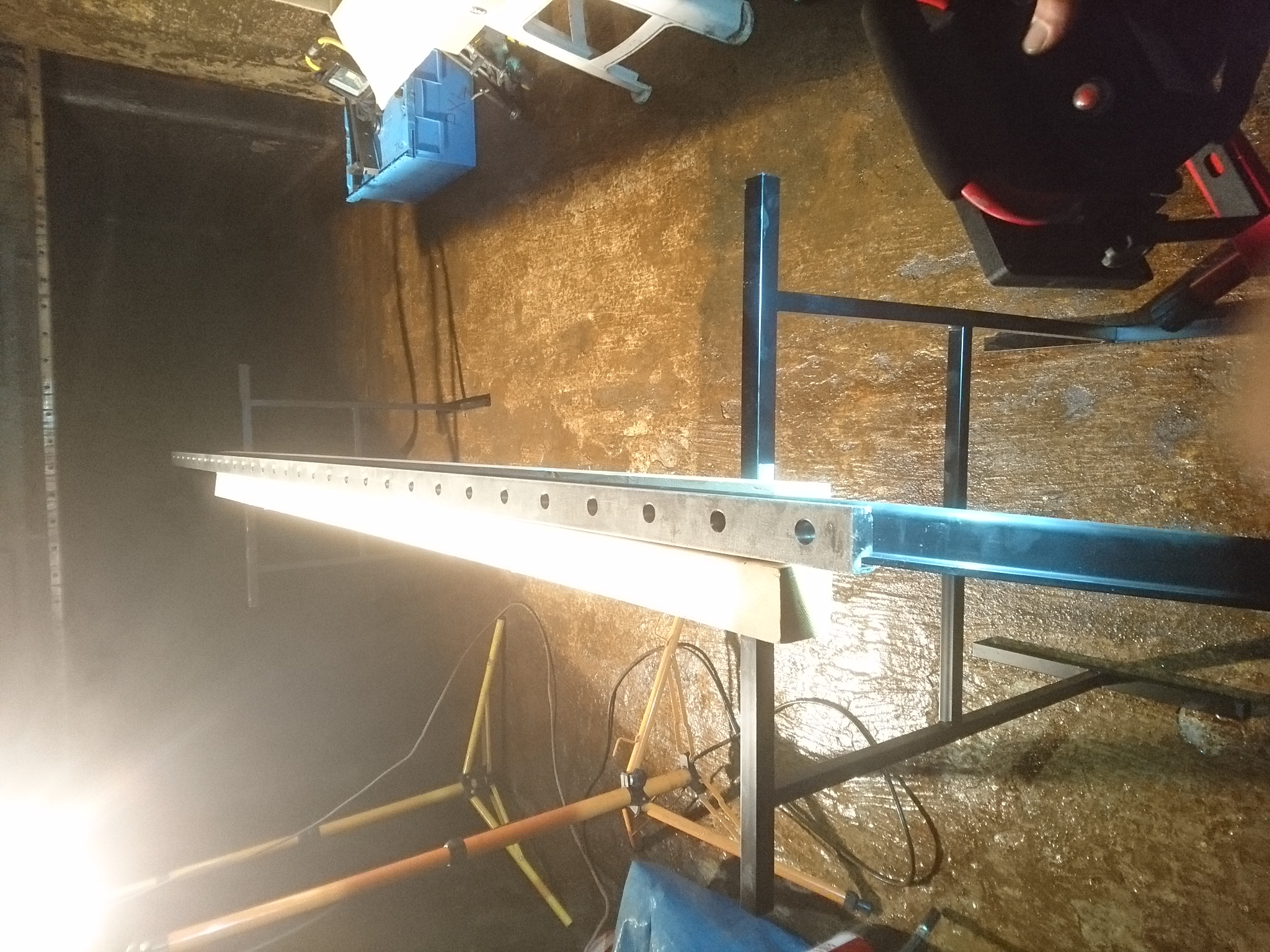

To meet customers’ expectations, PXL SEALS offers a solution of frames or semi-frames made in our workshop. This range of comprehensive services saves time during assembly by minimizing the number of junctions to be carried out on site in conditions that may be difficult and by guaranteeing more reliable joints.

The frames are made from profiles of the PROSEAL range generally obtained by extrusion.

A wide range of standard references is in stock, but PXL SEALS is also able to offer profiles with specific dimensions.

What material options for valve frame seals?

EPDM - HydroRubber type materials are used by PXL SEALS to manufacture valve frame seals. Indeed, they answer both to the application issue and limit the environmental impact by replacing the Polychloroprene traditionally used by a more ecofriendly material.

This type of material is less harmful to the environment, does not contain chlorine and has excellent mechanical characteristics, in accordance with the various specifications of major clients.

Other materials are also available, according to the needs and applications.

Which challenges for valve frame junctions?

Framed gate frames can be exposed to constraints such as water flow and significant abrasion due in particular to the presence of sediment and dead wood in the water.

On the other hand, the bonding areas may all present defects in the short or medium term (cracks, detachments, ruptures) which increases the risk of leaking.

Which junction options for valve frame corners?

In order to fix the issues of cold bonding of the seal profiles, PXL SEALS offers several alternatives:

- The molding of corner blocks which are then joined to the lengths of profiles. The joined zones (by gluing) are located in the straight lengths in order to minimize the risk of weakness of the frame.

- Hot joining by adding material: in the most strategic cases, PXL SEALS limits the use of glue and uses the HLB "Hot Layer Bound" process developed by our design office.

Installation and adjustment of valve frame seals

In addition to the supply of profiles, finished or semi-finished frames, PXL SEALS also offers on-site intervention services for the installation and adjustment of valve seals.

When it comes to replacing a framed valve seal, it is necessary to adapt to the terrain, the technology and the initial design of the valve. In order to define the best solution, it may be useful to go on site and check the potential areas of fragility and risk of leaks.

On the other hand, it might be necessary to "shape" the parts so that they perfectly match the imperfections of the friction track.

In order to facilitate the mounting and make framed valves seals more reliable , PXL SEALS has developed technologies and solutions such as half-frames or complete frames.

PXL SEALS can carry out operations on-site to manage junctions and to adapt the sealing to the equipment.

Using PXL SEALS’ valve sealing solutions means choosing safety and saving time by limiting assembly time and the risk of leakage.

Contact us for more information on valve frame seals.

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |