ALL NEWS :

Tests on test benches and finite element studies: which tools are used to design your seal?

16/06/2021 - posté dans Experience

Whether you want to replace an existing seal or install a new one, PXL SEALS will determine the most suitable sealing solution for your application and requirements.

To fulfil this commitment, we use all of the tools at our disposal. Moreover, our expertise has been honed by a wealth of tried-and-tested experience in the sealing sector stretching back almost 30 years.

Tests on test benches

If this proves necessary, we are able to propose tests on test benches to validate the functionality of the sealing profile proposed.

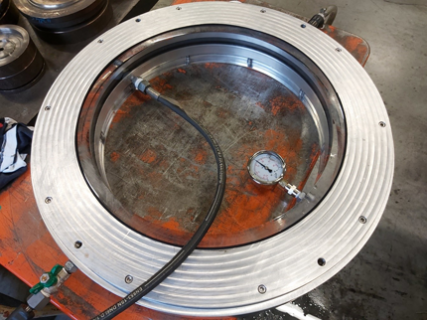

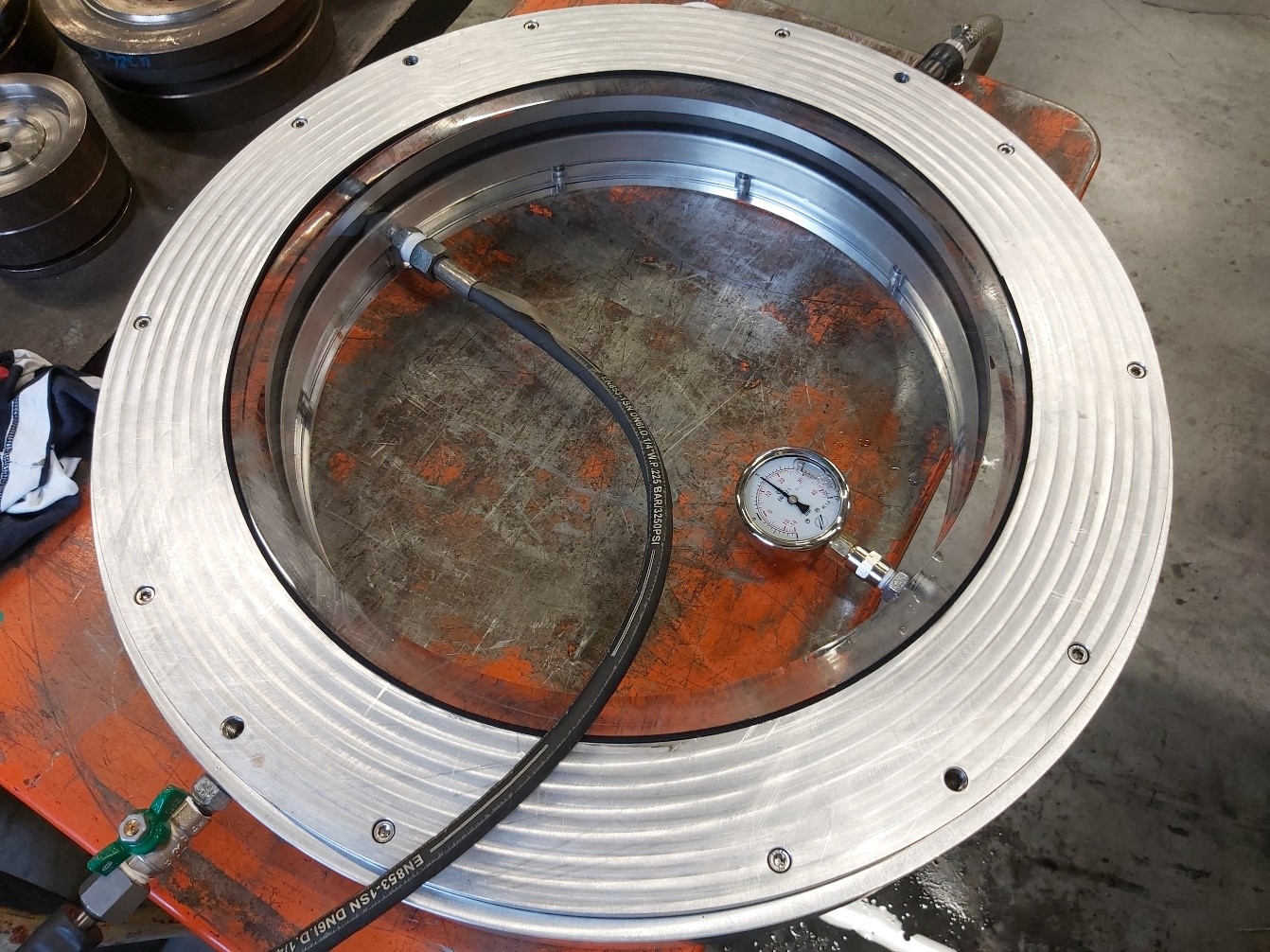

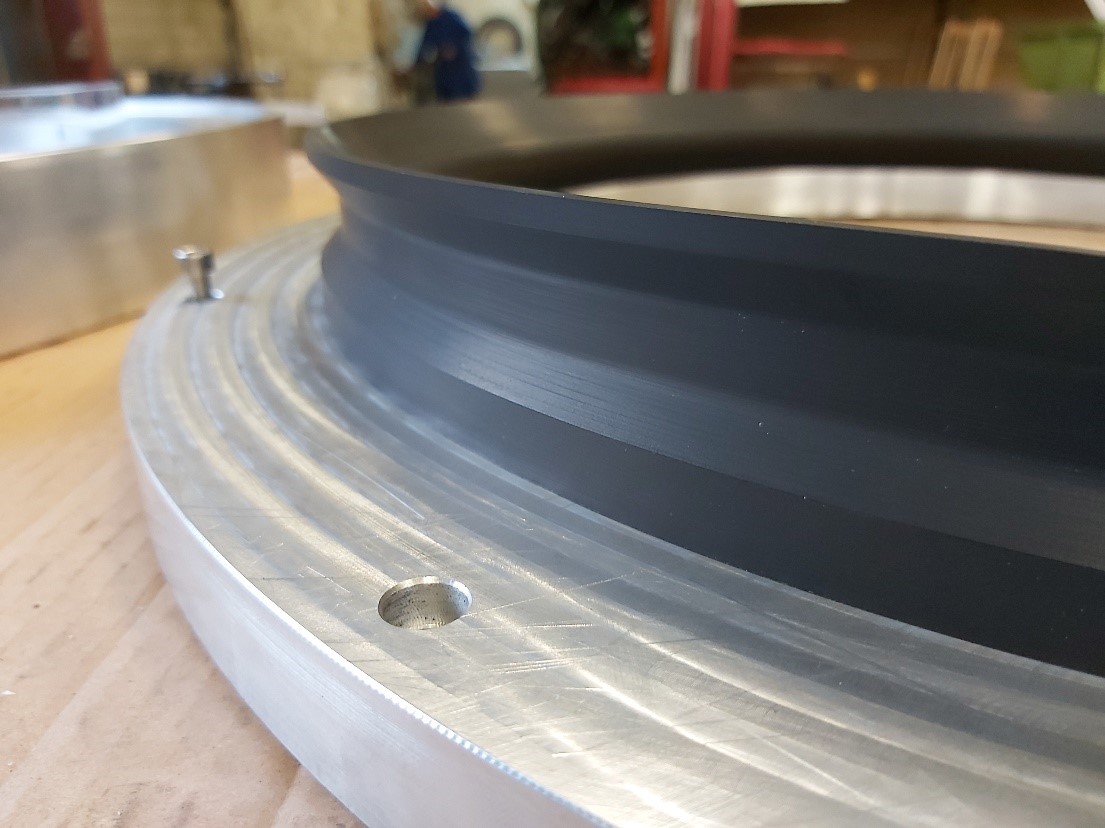

We were able to do this recently as part of the replacement of an inflatable-seal-type turbine shaft seal. This safety seal used during machine shutdowns was not completely satisfactory. We therefore created a test bench on which many different materials and profiles were tested.

The seal actuated under the effect of compressed air ensures sealing against water; these conditions were therefore reproduced on the created test bench.

Tested seal profile

Water-level display - seal actuated

Finite element studies

Apart from this type of test, we can also offer you finite element studies. These digital simulations are used to validate an existing profile, to optimise it, if necessary, or to design a new seal profile tailored to your project. These studies are used to validate the adaptability of the seal, the mechanical resistance of the seal or the frictional forces generated.

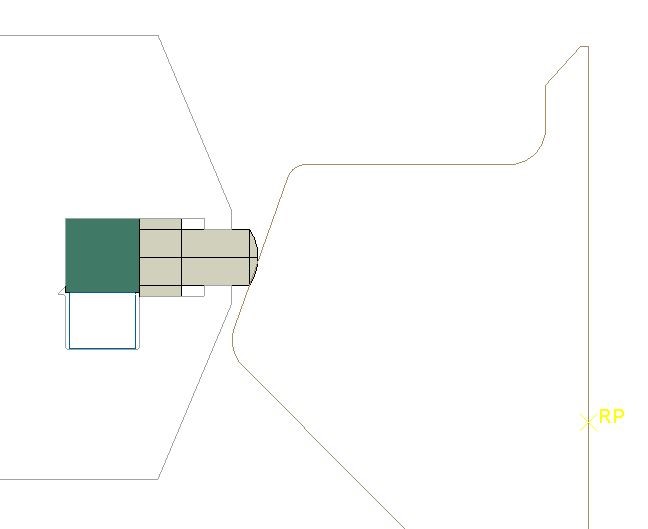

In the example given below, a study was carried out to define a lens seal profile more closely matching our customer’s requirements in order to ensure the sealing of a butterfly valve. The profile used at that time very soon started to exhibit significant deterioration associated with extrusion and tearing phenomena.

Géométrie de la vanne utilisée pour la simulation

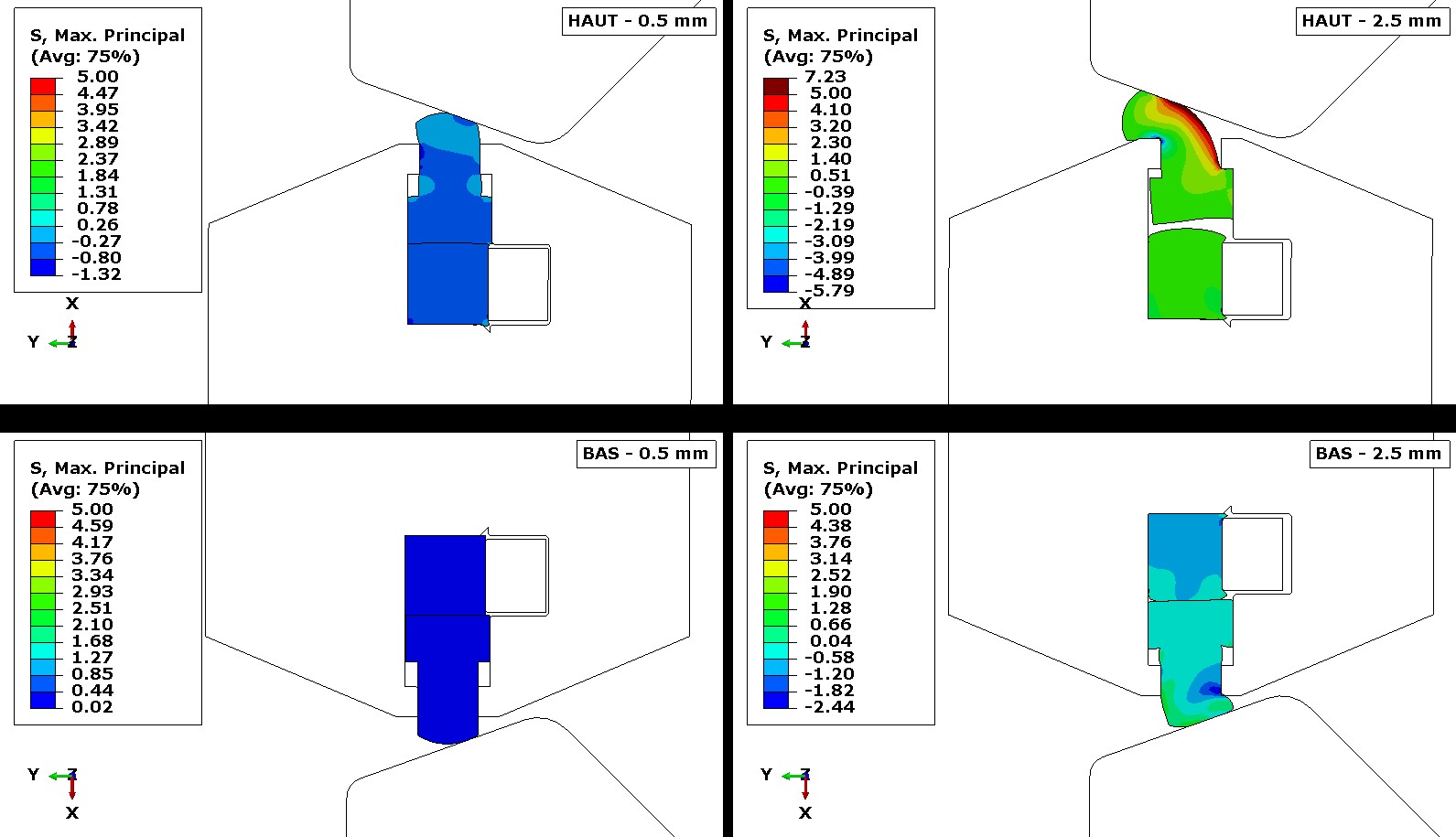

Digital simulation can be used to theorise the tearing phenomena noticed on the disassembled seals.

Tearing noticed on the old seal disassembled by the customer

Digital simulation result with the current assembly

Based on initial results, the digital simulation has, in particular, made it possible to define the compression rate to apply between the seal and the valve body, so as to ensure sealing while limiting as much as possible the damaging effects associated with the mechanical assembly’s geometry.

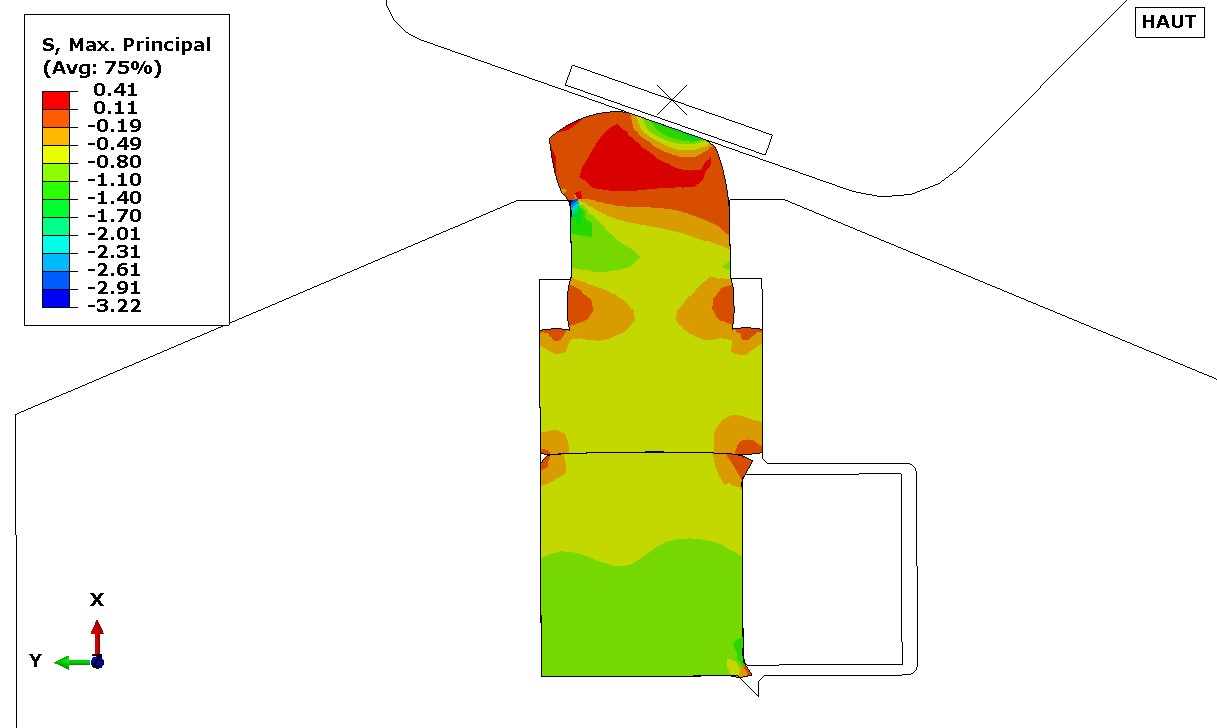

This made it possible to define a more functional seal and clamping.

Result of simulation with functional sealing

Once the results had been obtained, it was possible to manufacture the seal and install it, taking the digital findings into account. It was possible to ensure sealing with the new seal using less clamping force, which eliminated any tearing phenomena.

Mechanical testing of material characterisations

In terms of material characterisations, PXL SEALS is also able to carry out certain mechanical tests in order to confirm the properties of the materials proposed or determine the properties of materials supplied by our customers. If more extensive studies are required, PXL SEALS will work with approved laboratories to provide their customers with the required results (in the case of specific requirements, for instance).

Which tools/studies are used for which applications?

Of course, we are able to propose this type of study for any type of seal: seals for blade trunnions, for spherical valves (trunnions, mobile rings, etc.), for gate operating rings, to cite just a few examples in the hydroelectricity sector.

PXL SEALS also offers this expertise to other industrial applications fields, from large bearings to large-diameter seals, to offshore.

The PXL SEALS design office is available to act on any specific request.

Please contact us if you have any questions or would like to request a quote: https://www.pxlseals.com/contact

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |