ALL NEWS :

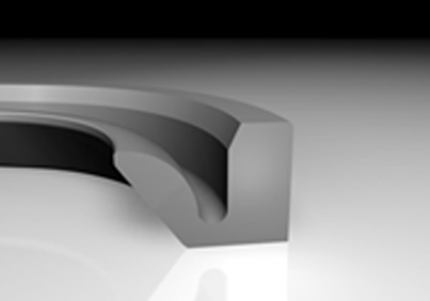

Jumbo seal for large bearings

07/11/2017 - posté dans Large bearings

For more than 20 years, PXL SEALS is one of the major suppliers of high-stakes sealing solutions, especially for hydroelectric applications. However, the range of skills of the society is not limited to hydroelectric applications. Indeed, PXL SEALS is also committed for many years to the development of sealing, qualified as “strategic”, destined to many sectors and especially the ones from offshore and “large bearings”.

This article will more particularly get interested in the “large bearings” sector and in the sealing profile developed for this purpose. When we speak about large bearings, it must be understood that it concerns various equipment, such as wind turbines, water turbines or equipment, destined to the tunnel infrastructure drilling. However, these different applications offer close functioning conditions. In one hand, the adaptability to slow and discontinuous rotation movements; on the other hand, the research of low pressure sealing (generally lower than 5 bars). Regarding divergent parameters such as functioning temperature or fluids in contact, they are considered during the material choice (mainly Nitrile, Self-lubricated Nitrile or Hydrogenated Nitrile).

Except the advantages of our Jumbo profile in terms of answering to the specifications, our manufacturing process offers the capability of answering all the dimensional ranges, from the smallest to the most important. In the “large bearings” sector, it is of course the big dimensions that are looked for, with components that can reach some meters of diameters, which is perfectly achievable through the process implemented by PXL SEALS.

In terms of mounting types, different options are possible depending of the mechanical conception of the bearing, and the profile developed by PXL SEALS is able to answer to several options, such as:

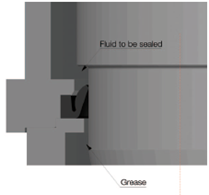

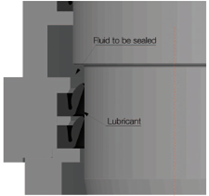

1. Sealing in one direction:

1] One seal mounting

2] Two seals assembled in “tandem”

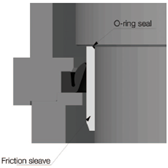

2. Sealing in two opposite directions:

In order to ensure maintenance, two scenarios can be considered, especially to answer wear problems of the sliding surface:

1] The use of interchangeable friction sleeve

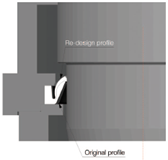

2] The use of a “new” seal profile

All the technical elements provided in this document are the result of many feedbacks which we have concerning the Jumbo profile since many years, completed by test campaigns conducted in collaboration with our main customers. For more information, you can consult the technical data, whose link is below, and contact us so that we can precisely study your request.

To download the technical data, click here.

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |