ALL NEWS :

Appraisal and maintenance of Hydro seals

12/10/2021 - posté dans PXL Seals

Appraisal and maintenance of Hydro seals:

What sort of on-site interventions can we carry out to optimise your equipment’s sealing?

In 2020, despite the complex public health situation, PXL SEALS carried out approximately 20 on-site interventions in France and internationally.

Here is an overview of the on-site interventions we have been carrying out for 25 years in hydropower plants on turbines, shafts, spray chambers, valves of all types, trunnions and actuators, etc.

Find out about the interventions we are able to offer you and read our feedback.

How does the on-site appraisal and maintenance of Hydro seals take place?

On-site appraisals: the hallmarks of success

Choosing a seal is not a trivial matter. “It’s leaking” does not necessarily mean that the seal is non-compliant or defective.

It may not be completely suitable for the operating conditions, but it could also be the housing that does not have the correct characteristics for optimum operation.

An on-site appraisal of the housing, the removed seal and the method used to fit/remove it is very often required before any intervention takes place.

A detailed analysis of the condition of the housings and information gathering about the behaviour of the seal and changes in it over time will enable the PXL SEALS design office to conduct a more realistic study and design the most suitable sealing solution.

Once the appraisal is complete, the seals are designed and then manufactured either at our premises or with the assistance of our partners.

On-site maintenance: from replacement of the seal to turnkey intervention

The PXL SEALS on-site intervention team carries out operations that can range from the simple replacement of a seal to the full management of the maintenance of the turnkey sealing system.

Replacement of seals without disassembling the installation

Once the seal has been designed and manufactured, we coordinate the dispatch of the material and send our teams to the intervention location.

Circular seals can be installed all in one piece. In this case, the system is disassembled and access to the housing is possible.

Otherwise, the seals can be installed without the need for disassembly by using one of three different bonding methods: cold bonding, the HLB hot bonding by material addition process and the MD on-site bonding process.

What is the difference between the various on-site bonding methods?

|

To find out more about the various on-site bonding options offered by PXL SEALS, and to learn about the properties of the bonds achieved, please take a look at the following article: https://www.pxlseals.com/fr/blog/solutions-de-jonction-et-de-moulage-sur-site

Full management of the on-site intervention

PXL SEALS can offer you a turnkey intervention service tailored to the installation type and requirements.

We can also help your teams fit seals.

A certified approach PXL SEALS has been certified according to standard ISO9001 for almost 15 years and plans to be certified according to standard ISO45001 by the end of 2021. Managing our quality and safety processes is our everyday focus. All of our intervention teams are trained by approved and authorised bodies. |

Examples of interventions for hydropower applications

On-site intervention in the hydropower sector is one of PXL SEALS’ specialities, particularly with respect to blade and turbine seals.

The company is, moreover, one of the main partners of the large hydropower operators and component manufacturers.

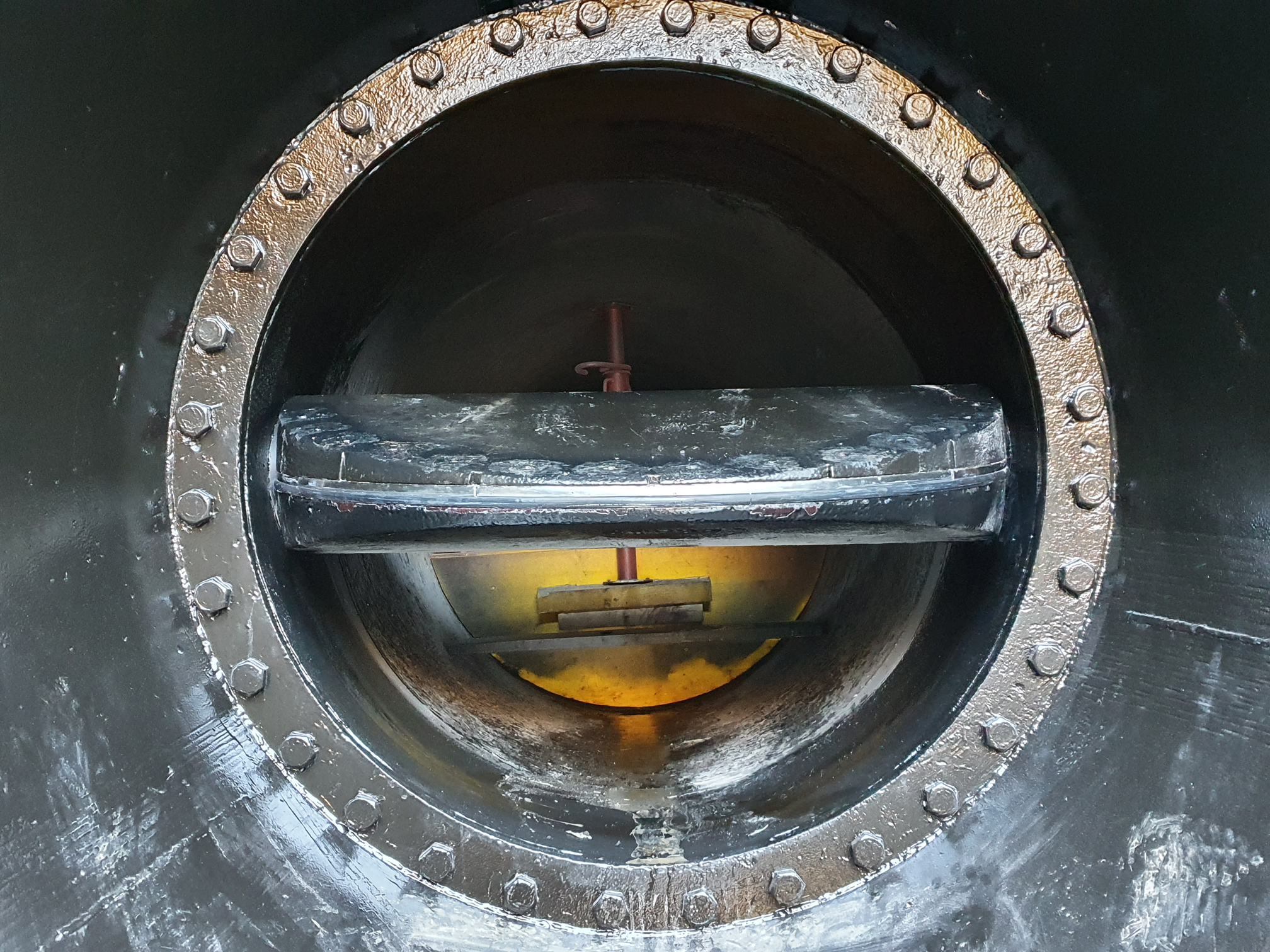

Replacement of butterfly valve seals on the lenses and trunnions

The connecting area between the trunnions and the lens is often critical, and this is where major leaks can be found. Services may vary depending on the valve condition and requirements.

- It is often necessary to conduct an appraisal in order to understand the cause of leaks.

- Our services will then range from design and manufacture, to assembly of the seals with disassembly of the old seals, right through to adjustment and even training.

From analysis of original plans to on-site assembly and adjustment of the various seals, PXL SEALS will support you every step of the way in your butterfly valve renovation projects.

Read several pieces of feedback on our replacement of butterfly valve seals: https://www.pxlseals.com/fr/blog/rehabilitations-des-etancheites-de-vannes-papillons

Valve seals

Seals on the spillways of a hydropower installation

On the Vaufrey dam, the valve appraisal was conducted to design and manufacture seal units.

The intervention team then visited the Vaufrey site for the forming and installation of the seals.

Find out more details about our on-site intervention: https://www.pxlseals.com/fr/blog/success-story-etancheites-de-l-evacuateur-de-crue-du-clapet-de-vaufrey

Sector valve seals

Following several seal failures, PXL SEALS has had a rethink and designed new seals with the aim of limiting leaks while improving the durability of the seals.

Take a look at this renovation of sector valve seals, side seals, threshold seals and connection seals with the corner unit, which was carried out on Vaufrey dam: https://www.pxlseals.com/fr/etancheites-laterales-de-seuil-et-liaison-avec-le-bloc-d-angle

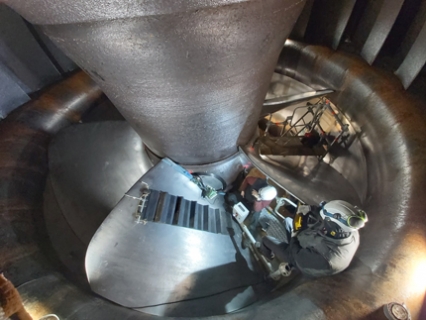

Interventions in tidal power stations

- FESSENHEIM G3-TURP Rev 0.jpg)

For more than 10 years, PXL Seals has been one of the main partners of the La Rance tidal power station for the maintenance and supply of key seals.

PXL SEALS attended to replace the seals of bulb unit blades using the patented “MD WAY” on-site vulcanisation process by moulding.

From cofferdam work to refurbishment, all of these steps were carried out by the PXL SEALS intervention team or under its supervision (a turnkey service provision).

Our intervention team also worked on sites where the seals are particularly critical, to seal a bottom valve so that the teams could carry out repairs, for example.

Interventions for high-stakes hydro equipment

In particular, PXL SEALS has designed valve seals for the Hongrin and Punt dal Gall dams.

The valves on the Punt dal Gall dam must be regularly checked and renovated to ensure that the dam works properly and residents are safe.

With PXL SEALS having successfully completed the Valve seals for the renovation of the Hongrin dam, it was therefore natural that HYDRO EXPLOITATION called upon the expertise of PXL SEALS for its high-stakes seals.

Designing valve seals to renovate the guard valves while meeting all the constraints of the site and ensuring the safety of those involved: that was the challenge faced by PXL SEALS.

Once the seals had been made by extrusion, the parts were then assembled on-site by the PXL SEALS ON-SITE intervention team.

To find out more, please visit: https://www.pxlseals.com/fr/punt-dal-gall-etancheites-a-fort-enjeux

PXL SEALS combines 20 years’ experience with a high degree of expertise and responsiveness, as well as a close relationship with its customers, to achieve successful on-site interventions.

Would you like to receive some information to prepare for an intervention? Contact the PXL SEALS team right away.

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |