ALL NEWS :

Sealing solutions for innovative firms

02/10/2019 - posté dans High-technology industries

PXL SEALS specialises in the design, manufacture and installation of high-performance guidance and sealing systems.

Once it has studied the specific characteristics of your projects, our design office will advise you on the most appropriate sealing solution. Whether you require standard or made-to-measure seals, we have a wide selection of materials that are suitable for your business sector.

Thanks to our equipment and the PXL SEALS manufacturing workshop, we can design seals that are tailored to your specific needs.

The expert in technical seals for industry

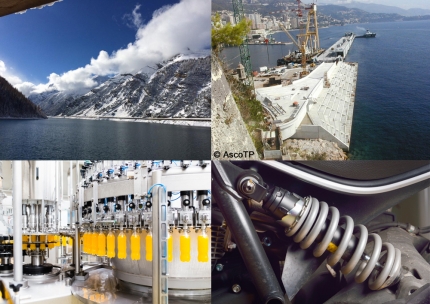

PXL SEALS, which is recognised as the specialist in the field of high-stakes guidance and sealing systems by hydropower producers and operators, is also a key player in numerous industrial and high-technology sectors.

Motorcycle and motor racing:

Applications: seals for shock absorbers, clutch master cylinders, gear boxes, actuators, forks, engines, kinetic energy recovery systems, pumps, transmission shafts, etc.

Advantages of PXL SEALS solutions:

- Reduced friction and hysteresis (seals for pistons, rods and scrapers)

- Very high speed, linear or rotation

- Reduced wear

- High-precision seals for repeatability of performance

Agri-food:

Applications: seals for bottle-corking, -filling and -blowing machines, aseptic machines, dosing pistons, swivel joints, etc.

Advantages:

- Materials are designed for contact with food, EC 1935 and FDA, ANIA

- 40-bar applications

- Friction without lubrication, dry air

- A comprehensive range of thermoplastic and elastomer parts

- Complete pistons for dosers

- Definition of high-performance membranes and bellows

- The option to mark parts for complete tracking

Hydraulic:

Applications: seals for hydraulic and pneumatic actuators, hydraulic presses, speed increasing gear, etc.

Advantages:

- Mixes for ceramic coating applications

- Heavy-load guidance parts

- Solutions designed for small movements and high-frequency applications

- Definition of low- or high-temperature systems

- Large diameters

Medical and pharmaceutical

Applications: seals for packaging machines, blenders, mixers, etc.

Advantages:

- Materials available with pharmaceutical approvals

- A wide range of materials

- High-quality machining to ensure that any surface faults are very minor

- Friction without lubrication, dry air

- Option to mark parts for complete tracking

Iron and steel industries:

Seals for actuators, rolling mills, ovens, etc.

Chemical and petrochemical industries

Applications: seals for pumps, valves and fittings, subsea valves, etc.

Advantages:

- A wide range of materials for high and low temperatures

- Large diameters available

- Static and dynamic applications

- High-pressure solutions, with or without anti-extrusion rings

Marine:

Applications: seals for stabilisers, shaft lines, pods, steering equipment, marine turbines, etc.

Advantages:

- The option for open seals (dryable, endless)

- Special guidance parts for marine use

- The provision of comprehensive solutions (cartridges)

- Assembly and welding on site

Materials that can rise to the challenges of sealing

In order to offer you sealing solutions that perfectly complement your applications, PXL SEALS has designed a very comprehensive range of products made from materials selected for their performance qualities. PXL SEALS offers both standard seals and solutions that are specifically tailored to your application.

Depending on the particular constraints, the following materials are used to manufacture our seals and sealing systems:

- PTFE and modified PTFE (empty and filled)

- Special PE and UHMW PE

- PEEK

- PU

- PVDF

- POM

- Elastomers (NBR, HNBR, FPM, FFPM, EPDM, VMQ, etc.)

- PXLKOT( heavy-load composite materials)

Regarding contact with food, the materials in our sealing systems comply with EEA regulations EC 1935/2004 and EC 10/2011 (relating to plastic materials), EU REACH regulations and FDA standards, 3-A sanitary standards and USP Class VI standards, etc.

They are also resistant to the cleaning agents used in the food and pharmaceutical industries (cleaning in place [CIP]) and to the sterilisation in place (SIP) processes.

A team of engineers and technicians specialising in sealing solutions will take care of your request and your project in order to come up with the optimal sealing and guidance solutions. The PXL SEALS design office, supported by our R&D laboratory, is able to conduct all of the necessary research, including 2D or 3D finite element simulations (digital simulations).

Please feel free to contact us.

We would love to be able to help you develop your future projects!

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |