ALL NEWS :

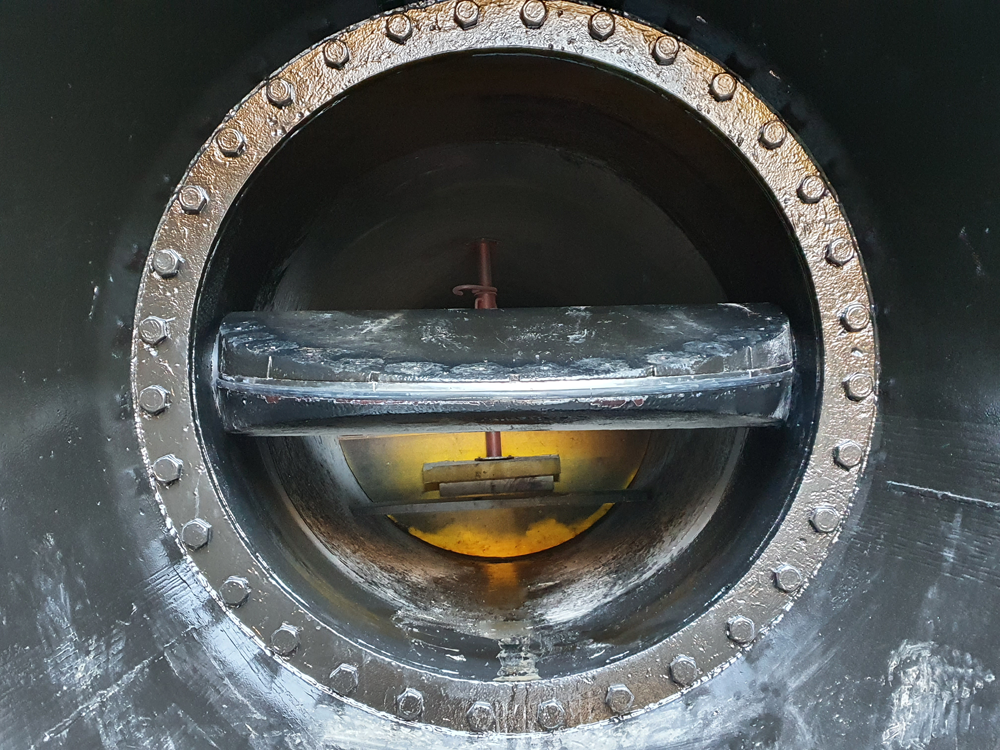

Refurbishment of butterfly valve seals

12/05/2021 - posté dans Experience

Our customers’ requirements vary from one piece of equipment to another, which is why PXL SEALS has been offering various butterfly valve refurbishment options for over 20 years.

The connecting area between the trunnions and the lens is often critical and where major leaks can be found.

Services may vary depending on the valve condition and requirements:

- Design of a new tailored solution

- Attendance on site with extraction of the old seals

- Appraisal and preparation of the housings

- Assembly of miscellaneous seals (redesign or renewal of the existing solution), adjustment of seals

It is often necessary to carry out an appraisal in order to understand the cause of leaks. Our services will then range from design and manufacture, to assembly of the seals with disassembly of the old seals, right through to adjustment and even training.

From analysis of original plans to assembly and adjustment on site of the various seals, discover how PXL SEALS will support you every step of the way in your butterfly valve renovation projects.

Seals for multiple butterfly valves

This seal is critical on certain valves because a leak may lead to the complete shutdown of the installation.

This seal is critical on certain valves because a leak may lead to the complete shutdown of the installation.

Although we mainly operate in the hydro field, we are also called upon to fix other types of industrial leaks, including in wastewater networks, steelworks, fluid transport, etc.

Very often, axial butterfly valves, with trunnion and lenses on the same axis, are involved. However, we also carry out work on butterfly valves with offset lenses.

The areas of a butterfly valve requiring sealing are the lens seals, trunnion seals, flange seals and lead seals.

PXL SEALS offers sealing solutions for each of these areas as well as a tried-and-tested lead seal replacement solution.

What are the stages involved in renovation?

For the majority of projects, the typical plan for a butterfly valve renovation is as follows:

- Analysis of plans

- Technical proposal

- Appraisal

- Assembly and forming in the workshop, as applicable

- Final adjustment on site, etc.

A few examples of butterfly valve seal replacement

We carried out several projects in 2020, including one full service involving the replacement of all seals.

- Renovation of trunnion and lens seals, Poutès-Monistrol dam (Haute-Loire department, France)

This on-site service was the most recently completed one.

This on-site service was the most recently completed one.

Even the design and manufacture of the seal were exceptional, as the seal had to be tailored to a 1,800-mm-diameter lens!

PXL provided its on-site services in five steps:

- Removal of the old lead seal and the seal of the valve in place

- On-site appraisal of the downstream flange seal

- Appraisal of the valve’s lens and trunnion seals (valve disassembled beforehand by the client; valve body in the vertical position and the diaphragm horizontal)

- Assistance with assembling the lens seal: forming the ends of the spreader and lens seal with adjustment of the lens seal

- On-site assembly of the downstream flange seal

- Radial adjustment of the lens seal on site

The second example concerns our on-site replacement/refurbishment of the seals of two butterfly valves, bottom valves, without disassembling the lens (Maury, Brassac, etc. dams).

- Refurbishment of butterfly valve seals without removing them (valve in the pipe) when it is very difficult or almost impossible to remove the valve

In this case, the problem is to ensure a perfectly sealed trunnion-lens connection. This may be possible depending on the type of seal to replace and the state of deterioration of the valve seats near the trunnions.

CATEGORIES

TAGS

ARCHIVES | Février | |||||

| Lun | Mar | Mer | Jeu | Ven | Sam | Dim |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |